With the gradual acceleration of the modernization process, tall buildings have sprung up like mushrooms after a spring rain, and slowly spread from the city to the surrounding towns over time. When building these tall buildings, in addition to the necessary bricks, cement and steel bars, there are also necessary building templates.

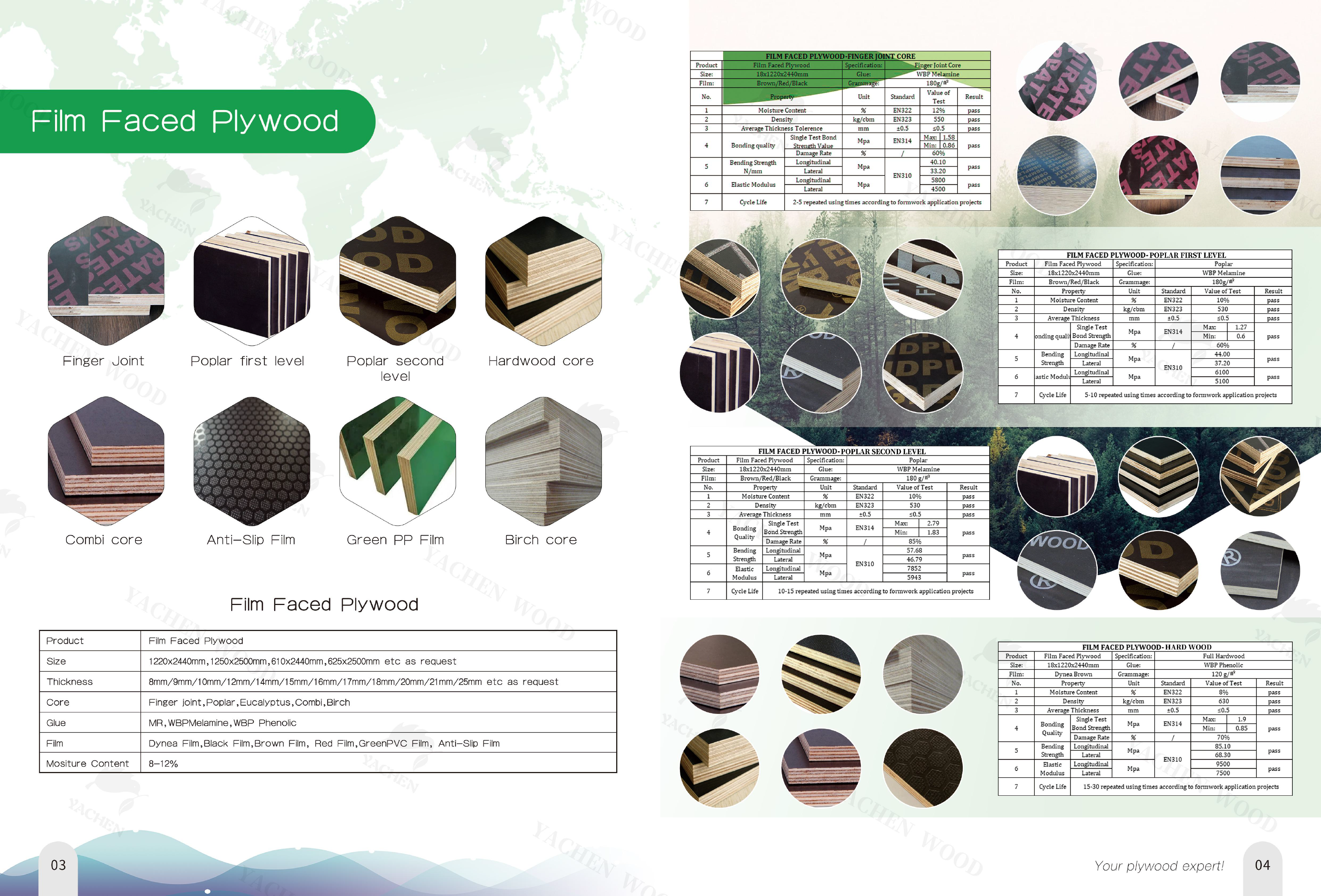

Speaking of architectural formwork, people who are not in contact with the construction industry may be unfamiliar, and they rarely have the opportunity to see it. Building formwork is an indispensable tool for modern building construction. Most people distinguish building formwork by color, the most common is black plywood covered with triamine film paper, in addition to red building formwork, brown building templates, and even green building templates. So what’s the difference between them?

Let me briefly introduce the basic knowledge of plywood for construction.

The building formwork is the temporary support structure formwork on the construction site. The purpose of using building formwork is to ensure the quality of the concrete fixing bracket. The wooden formwork is easy to use, can speed up the construction progress and reduce the construction cost. The commonly used color templates on the construction site can be roughly divided into black building templates, red building templates, brown building templates and green building templates.

Red building formwork was more common ten years ago. Compared with the more common black building formwork now, the surface of the formwork is coated with red glue (some are painted with yellow paint). The color of the side paint of the red building formwork is mainly yellow edge, red edge and black edge, which can be determined according to the requirements of customers and manufacturers. Some building formwork manufacturers also spray-paint their logos and company branding on the edges of the formwork.

The difference between the two is that under normal circumstances, black building formwork of the same size is more expensive than red building formwork, with better weight and quality, and more times of use. The main reason is that black building templates are generally film-coated boards, and the surface is covered with melamine film paper, which has good waterproof and wear-resistant characteristics, and effectively protects the inner layer of building templates. The red building formwork is generally only glued on the surface, so the overall performance such as waterproofing is definitely worse than that of the black building formwork.

As for the green building formwork, its surface is covered with green plastic film. Compared with the melamine paper covered by the traditional black building formwork, it has better waterproof and wear-resistant properties. It can be reused for 25-35 times, and it is easy to disassemble, easy to demould and not stick to cement. The surface is smooth and beautiful, and it is light in weight. But the only disadvantage is that the price is more expensive than ordinary black building templates.

The advantages of green bilding formwork.

1. Flat and smooth. The splicing of the plastic formwork is tight and smooth, and the surface and smoothness of the concrete structure after demoulding exceed the technical requirements of the existing clear water formwork, and there is no need for secondary plastering, saving labor and materials.

2. Light and easy to install. It is light in weight and strong in process adaptability. It can be sawed, planed, drilled, and nailed. It can be formed into any geometric shape at will to meet the needs of various shapes of building formwork.

3. Easy demoulding. The concrete does not stick to the surface of the board, no release agent is required, it is easy to demould, and it is easy to clean the dust.

4. Stable and weather-resistant. High mechanical strength, no shrinkage, no swelling, no cracking, no deformation, stable size, alkali and corrosion resistance, flame retardant and waterproof, rodent and insect repellent under the temperature condition of -20°C to +60°C.

5. Good for maintenance. Plastic forms are non-absorbent and require no special care or storage.

Yachen Wood has gone through hard work and hard work in recent years. In the fierce market competition, it creates quality with science and technology, creates brand with quality, and develops the market with brand quality, so that the enterprise continues to grow and develop. The pine formwork with phenolic glue surface produced by our factory is smooth and easy to demould, and the number of times of repeated use is much lighter than that of bamboo formwork. Experiments have proved that it is the best choice to choose the building formwork produced by our company. The building formwork produced by our factory sells well all over the country. The products are widely used in the construction industry, and are well received by users for their high quality and low price.