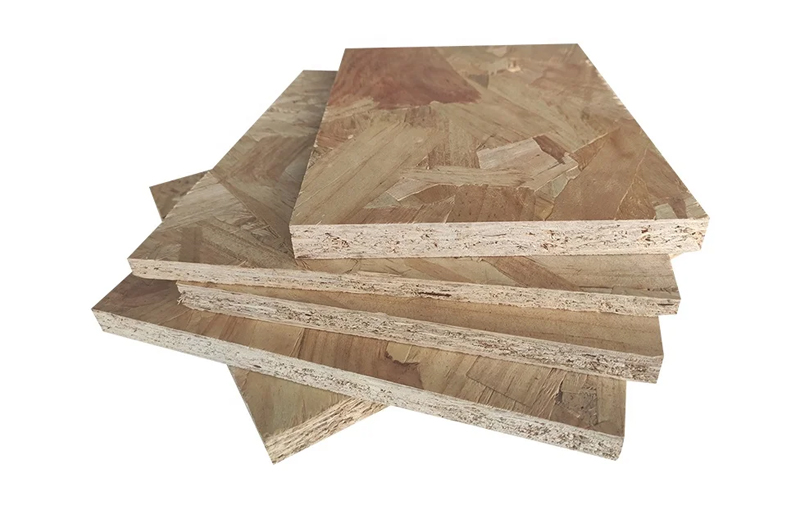

OSB (Oriented Strand Board) plywood is a board made of elongated directional fiber sheets that are interlaced and bonded with resin glue. It is a versatile building material that is strong, durable and affordable. The following is an introduction to OSB plywood production:

Raw material selection: The raw material for making OSB plywood is mainly wood. High-quality woods such as pine, fir and birch were chosen mainly for their uniform fiber structure and low resin content.

Cutting wood: Select the appropriate wood for cutting. The wood is cut into long, thin pieces of fiber, generally called flakes.

Pressing and Steaming: The fine slices are steamed to increase softness and plasticity, then heat-pressed. During the hot pressing process, the thin pieces are placed in a special plywood mold, and under the conditions of high temperature and pressure, the adhesive is activated, causing the fiber pieces to bond to each other.

Resin adhesive bonding: Resin adhesives, such as urea-formaldehyde resin or phenolic resin, are added during the production process of plywood. These resin glues have excellent adhesive properties and can tightly bond fiber sheets together under high temperatures and pressures.

Forming and cooling: After hot pressing, the formed OSB plywood is sent to the cooling area for cooling, allowing it to gradually cool down.

Processing and Trimming: The cooled OSB plywood is processed and trimmed to remove unqualified corners and obtain the desired size and shape.

Inspection and quality control: The manufactured OSB plywood must undergo strict inspection and quality control to ensure that it meets relevant standards and specification requirements.

Packaging and Shipping: After completing the inspection, the OSB plywood is packed and prepared for shipment to the end user or sales channel.

The manufacturing process of OSB plywood is simple and efficient, utilizing smaller wood particles and reducing the need for natural forest resources. It is widely used in the construction industry for the construction and decoration of walls, roofs, floors and other structures.

OSB (Oriented Strand Board) is a multi-purpose building board made of elongated directional fiber sheets that are staggered and bonded with resin glue. It has many advantages and therefore has wide applications in construction and other fields. The following is an introduction to the application of OSB:

Building structures: OSB is widely used in the construction field for the structural construction of walls, roofs and floors. Its strength and durability make it an ideal alternative to traditional plywood and solid wood materials. OSB also helps improve the strength and stability of buildings.

Interior decoration: OSB plywood can be used for interior decoration, such as ceilings, interior wall panels, door and window frames and furniture making. Its surface texture is unique and can provide a modern and distinctive design style. When doing interior decoration, you can choose the original OSB surface for painting or covering, or you can choose OSB that has been pre-painted to reduce the construction process and time.

Packaging materials: Due to the strength and durability of OSB material, it is also commonly used in the packaging industry to make boxes, pallets, and other shipping containers. In these applications, OSB can provide structural stability and protect cargo from damage.

Furniture Manufacturing: OSB plywood is also widely used in furniture manufacturing. Due to its strength and durability, it can be used to make tables, chairs, cabinets, and other furniture. In addition, OSB can also be used to make decorative surfaces for indoor furniture, giving the furniture a different appearance by painting, covering it with stickers or other decorative materials.

Stage and display construction: Due to its strong structure, easy processing and handling, OSB plywood is also commonly used in stage and display construction. It can be used to make stage floors, booths, showcases and other stage and display structures.

In short, OSB plywood, as a multi-purpose building panel, is widely used in construction, interior decoration, packaging, furniture manufacturing, stage construction and other fields. Its sturdiness, durability and affordability make it ideal for many projects.