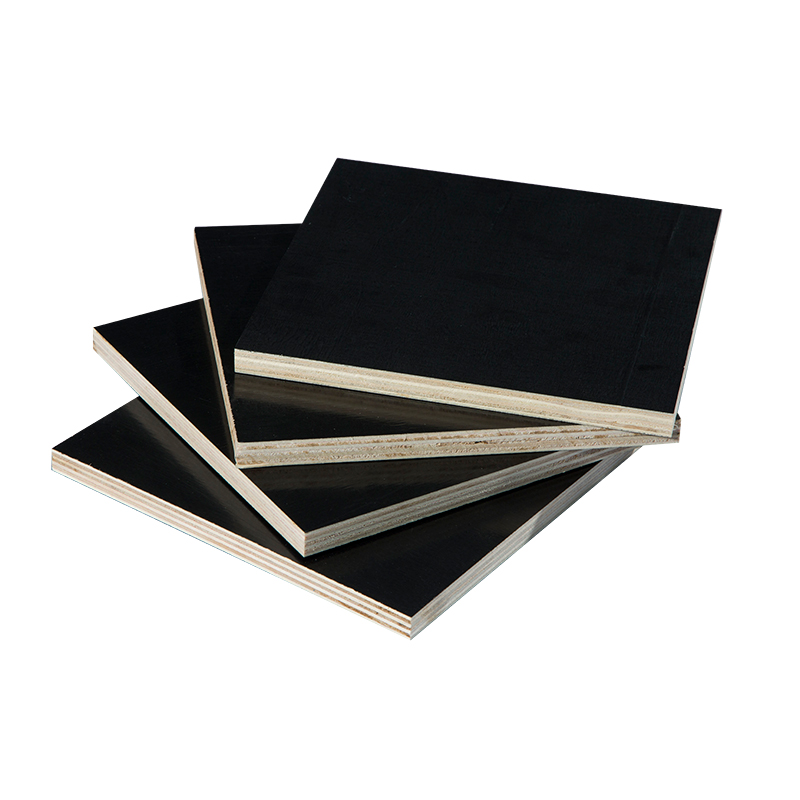

Film faced plywood is a type of prefabricated building components that are used to design and build houses, commercial and industrial buildings, etc. The use of film faced plywood can improve the quality of construction projects, reduce construction time, reduce costs and increase efficiency.

There are many advantages to using film faced plywood, not the least of which is that they reduce the amount of work on the construction site. Prefabricated film faced plywood can be prefabricated and installed directly on the construction site, eliminating the need for extensive cutting and processing on site. This not only saves time and manpower, but also reduces waste. In addition, the use of film faced plywood increases the accuracy and consistency of the building structure, making the final result more coherent and aesthetically pleasing.

In addition, film faced plywood can develop various film faced plywood standards as needed to adapt to different building styles, shapes and sizes, allowing for perfect customization. In the production of prefabricated film faced plywood, modern CAD software technology can be used to further improve precision and accuracy to ensure that the film faced plywood is consistent with the requirements of the architectural design.

In summary, film faced plywood has become an important part of the construction industry because they can increase construction efficiency, save costs, reduce construction quality issues, and provide consistency and accuracy. Whether it is a small residential building or a large commercial and industrial building, film faced plywood can play an important role and help create a beautiful, modern and boutique building structure.

In addition, film faced plywood can reduce project risks and improve safety. Because formwork is made and inspected in a factory, there is greater control over the quality of materials and processing, reducing the occurrence of structural defects and construction quality issues. This helps reduce the risk of construction accidents and improves building safety.

In addition, the use of film faced plywood also helps save resources and protect the environment. Prefabricated formwork can be produced in factories, reducing scrap and construction waste on site. In addition, the template can be reused, reducing resource consumption and environmental pollution during the construction process. This is in line with the concept of sustainable development and is environmentally friendly.

In the construction industry, film faced plywood has been widely used. Whether it is a residential building, a commercial building or a public building, using film faced plywood can improve project efficiency, reduce waste, and ensure construction quality and safety. In addition, with the continuous development of technology and materials, the design and production of film faced plywood are also constantly innovating to meet the changing construction needs.

Overall, film faced plywood is a modern, efficient and sustainable construction solution. By using film faced plywood, we can achieve higher quality, safer and more sustainable construction projects, providing a better built environment for society and people’s lives.

However, there are some limitations and disadvantages to using film faced plywood. First, the formwork may be limited by materials and manufacturing processes, making it difficult to meet some customization requirements, which may not be suitable for some special building designs. Secondly, the cost of film faced plywood can be relatively high, especially for smaller projects, and prefabricated formwork can increase construction costs and have an impact on financial budgets. In addition, because prefabricated formwork is typically larger and heavier than on-site fabrication and processing, it may require more equipment and manpower, making transportation and installation more difficult.

In summary, although there are some limitations and disadvantages to using film faced plywood, its advantages are still obvious. Film faced plywood can improve construction efficiency, reduce waste, improve the accuracy and consistency of building structures, while also reducing construction accidents and environmental pollution. With the continuous improvement of film faced plywood technology and manufacturing processes, the advantages of film faced plywood will become more prominent and bring more development opportunities to the construction industry.