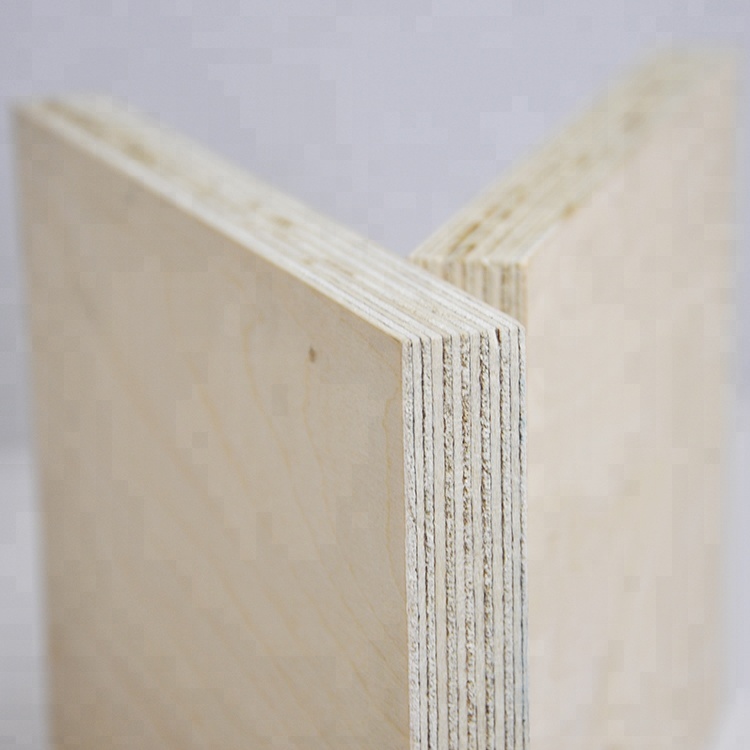

Birch plywood is a commonly used building material made from multiple layers of birch veneers stacked crosswise, with the grain direction of each layer perpendicular to the adjacent layer. This cross-laminated structure gives birch plywood its excellent strength and durability.

Birch plywood offers several advantages. First, it has excellent mechanical properties. Due to its cross-laminated structure, birch plywood exhibits excellent flexural and tensile strength and is able to withstand large loads. Secondly, birch plywood has good stability and anti-deformation properties. Compared with solid wood, its expansion and contraction coefficients are lower, it is not easily affected by humidity changes, and it can be used in various climate conditions. In addition, birch plywood has good wear resistance and durability and can withstand long-term use and wear.

In addition to its superior performance, birch plywood also has better processability. It can be processed through cutting, drilling, planing and other processes, and can be customized into various sizes and shapes according to different needs, which is very convenient and practical. At the same time, because the surface of birch plywood is smooth and flat, and the texture is uniform, it is very suitable for surface finishing treatments, such as painting, painting, etc., to increase its aesthetics.

Birch plywood is widely used in construction, furniture manufacturing and vehicle manufacturing. In construction, it is often used as a structural material for floors, wall panels, roofs, and formwork, providing strength and stability. In furniture manufacturing, birch plywood can be used to make components such as furniture frames, trays and drawers. In vehicle manufacturing, it is often used to make body parts and seat support structures.

In short, birch plywood has become a favored building material due to its excellent properties and diverse application fields. Its strength, stability and durability give it long life and good use value, making it one of the preferred materials in many industries.

In addition to the advantages introduced above, birch plywood has some other features worth noting. First of all, it is light and strong, with good portability and easy assembly, making it more convenient to use on the construction site. Secondly, birch plywood has better environmental performance. Compared with solid wood, it produces less waste during the production process, does not waste resources and reduces the impact on the environment. In addition, birch plywood also has good sound insulation properties, which is very suitable for places where a quiet environment needs to be maintained.

It’s important to note that birch plywood also has some disadvantages. Because it is made of multiple layers of wood flakes stacked, cracks on the cutting surface or glue leakage during the stacking may occur during the processing, which affects its use. In addition, if the density is too high or it is subjected to excessive vibration or impact during use, birch plywood may also suffer from cracking and other problems.

In conclusion, birch plywood is a building material with many advantages and is suitable for a variety of industries and fields. When selecting birch plywood, materials of different sizes and thicknesses need to be selected according to specific needs and usage environments, and their quality must be strictly controlled.

In addition, birch plywood has good fire resistance. Due to the high flame retardancy of the adhesive in its structure, birch plywood can effectively prevent the spread of fire when a fire occurs and play the role of fire isolation. This has resulted in birch plywood being widely recognized for its fire safety in the construction sector.

In addition, birch plywood also has good moisture resistance. The production process of its glue and birch flakes makes it highly resistant to moisture and mildew, and can be used stably for a long time in humid environments. This feature makes birch plywood suitable for use in closed or moisture-prone places, such as kitchens, bathrooms, and basements.

In addition, birch plywood also has better surface flatness and balance. It has been processed and sanded during the production process to make its surface smooth, which can meet some application scenarios that require a smooth surface. At the same time, birch plywood has uniform strength in all directions, is not prone to distortion or deformation, and can maintain good balance.

It should be noted that the performance and quality of birch plywood are affected by the raw materials. Different birch plywood may be composed of veneers from different birch species and will vary in quality and performance. Therefore, when choosing, you should carefully understand the raw material sources and production processes of the product, and choose high-quality birch plywood that meets the requirements.

All in all, birch plywood is a versatile and stable building material. Its excellent properties include high strength, good durability, good fire resistance, and strong moisture resistance, making it widely used in construction, furniture manufacturing, vehicle manufacturing and other fields.