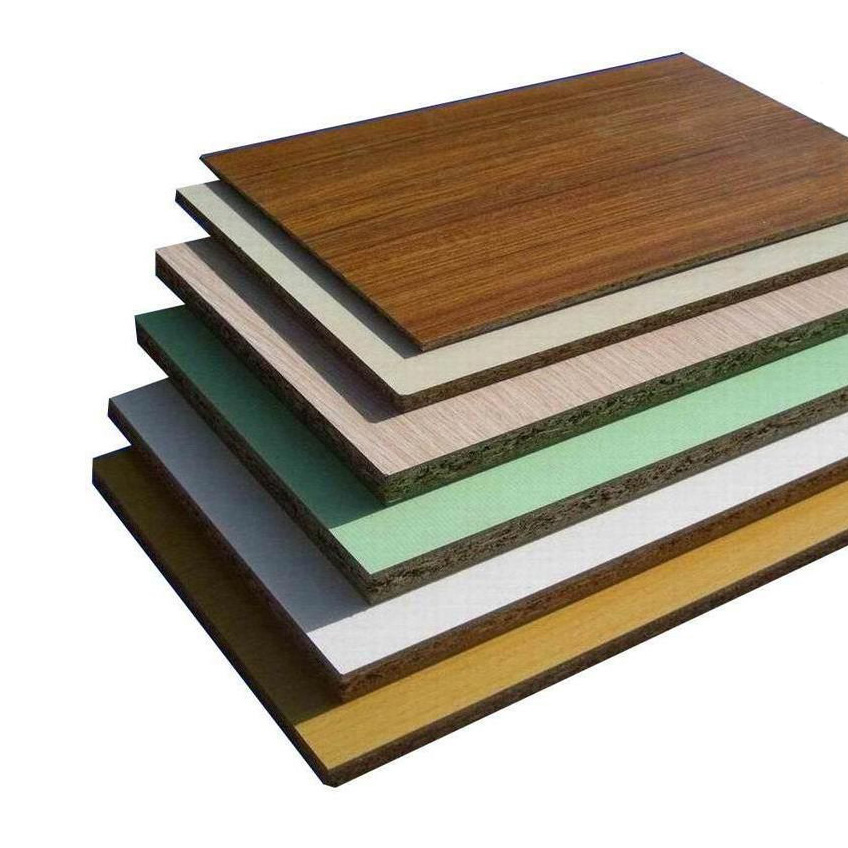

Density board is a commonly used decorative material, also known as medium-density fiberboard. It is an artificial board made of wood fiber or other plant fiber as the main raw material, processed under high temperature and high pressure. Density board is widely used in furniture manufacturing, architectural decoration, flooring, wall panels and other fields, and has strong stability and durability.

1. Types of density board

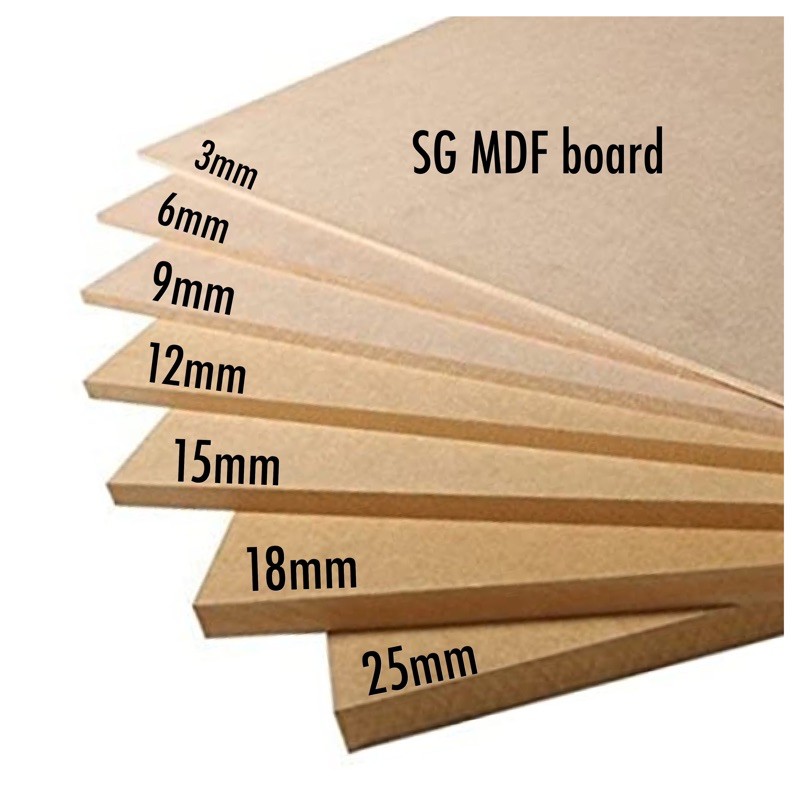

According to the thickness and density of density board, it can be divided into ordinary density board, thick density board and ultra-density board.

Ordinary density board: Ordinary density board generally has a density of 700-750kg/m³, and a thickness of generally between 2.5-30mm. It is suitable for furniture, decorative panels and other fields. Its surface is smooth and flat, easy to process, and is a commonly used material in furniture manufacturing.

Thick density board: The density of thick density board is 750-850kg/m³, and the thickness is generally above 30mm. It has better strength and stability and is suitable for occasions that require high load-bearing and durability, such as kitchen countertops, desks, floors, etc.

Ultra-density board: The density of ultra-density board is above 850kg/m³, and the general thickness is also above 30mm. It has higher density and hardness, and is suitable for fields with high requirements for board quality, such as industrial machinery, ships, aircraft, etc.

2. Characteristics of density board

High strength: Due to high temperature and high pressure treatment, density board has high density and uniform layer distribution, has high strength and stability, is not easy to deform and crack, and is suitable for occasions that need to bear weight.

Smooth and flat: The surface of density board is flat and smooth, easy to paint, spray and cut, and can produce various complex shapes and patterns, which is suitable for furniture manufacturing and decorative panels.

Easy to process: density board has good plasticity and processability, and can be processed by mortising, gluing, cutting, drilling and other processing according to different needs, which is flexible and changeable.

Environmental protection and health: density board uses plant fiber as raw material, is non-toxic and harmless, does not contain volatile organic compounds, does not pollute the environment, and meets green environmental protection standards.

Corrosion resistance: density board has good water resistance and corrosion resistance, is not easy to be damp and moldy, and is suitable for humid environments and long-term use occasions.

Long service life: MDF has been specially treated to be wear-resistant and scratch-resistant, not easy to change color and age, and has a long service life. It is an economical and practical material.

3. Application of MDF

Furniture manufacturing: MDF is widely used in furniture manufacturing. It can be used to make wardrobes, desks, bedside tables and other furniture. It has a smooth and flat appearance, rich colors and diverse shapes.

Wooden doors and cabinets: MDF is also commonly used to make wooden doors, cabinets, kitchen cabinets and other household items. Due to its high strength and durability, it is often selected as a kitchen countertop material.

Architectural decoration: MDF is also commonly used in architectural decoration fields such as wall panels, floors, cabinets, etc. It has high flatness and adjustable colors, which can meet various decorative design needs.

Industrial manufacturing: MDF is also widely used in industrial machinery, assembly lines, ships, aircraft and other fields, and has high requirements for the hardness and quality of the board.

In general, MDF, as a commonly used decorative material, has the advantages of high strength, smoothness, easy processing, environmental protection and health. It is suitable for furniture manufacturing, architectural decoration, industrial manufacturing and other fields, bringing convenience and beauty to people’s lives and work.