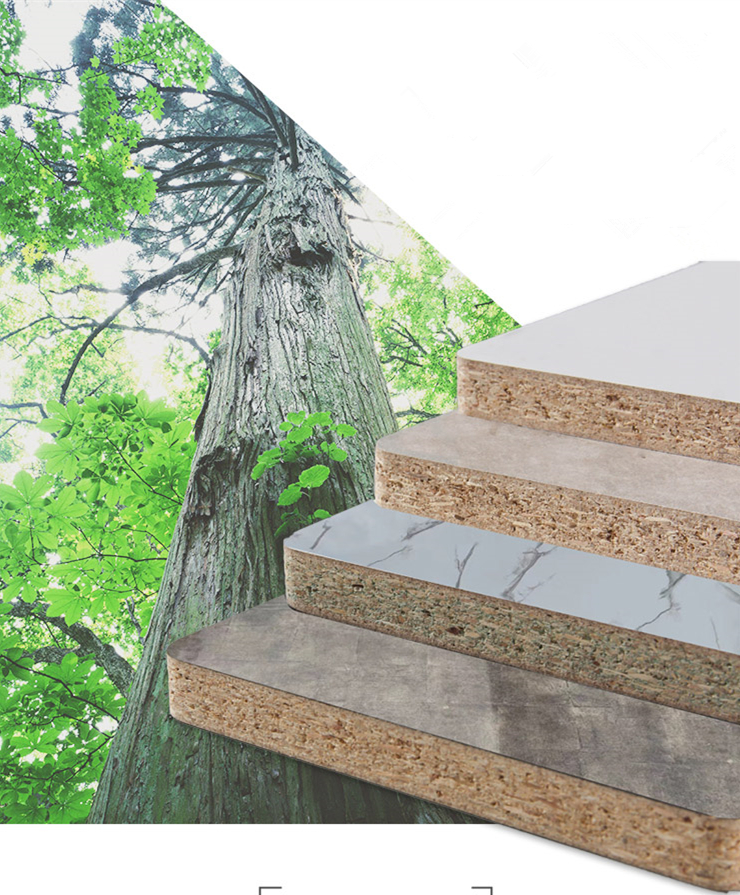

At present, why most of the domestic custom-made furniture uses particle boards, the cost must be the first consideration, but the use of particle boards to make custom furniture is not only cheap, but also related to the characteristics of particle boards.

Particle board is a kind of particle board. It was invented in Germany in the late 19th century. It has a history of more than 100 years. To a certain extent, particle board is a furniture material with mature technology and stable performance. Wide range, some big brands of custom furniture will use particle board.

Physical properties of particle board: strong stability

Compared with other boards, particle board has better anti-deformation, anti-cracking ability, gripping force, and moisture-proof ability. The strength of laminates is lower than that of multi-layer boards, finger-joint boards and density boards, but relatively speaking, particle boards are more stable and have strong adaptability to some complex indoor environments, such as humidity. Not easy to warp and deform.

The production performance of the particle board: it is easy to process

the granular shape inside the particle board, which is arranged in a cross-staggered arrangement. The particles are arranged in a certain direction, and its longitudinal bending strength is much larger than that of the transverse direction. This remarkable feature makes it easy to saw, sand, Planing, drilling, nailing, filing and other processing. Because of its particle structure, its ability to hold nails is very good. At the same time, the size of the particle board is relatively accurate, and the interior is dense, which is convenient for large-scale mechanized and electronically controlled production. Dense, not easy for large-scale processing.

The price advantage of particle board

In the case of the same environmental protection index, the price of particle board is relatively low, and in the case of relatively good quality and environmental protection, custom furniture merchants will definitely choose the relatively cheap one. At present, the main factor affecting the price of particle board is its environmental protection performance. The higher the environmental protection performance, the more expensive the price.

How is the environmental protection of particle board custom furniture

How is the environmental protection of particle board custom furniture? Particle board is made by crushing some solid wood leftovers and other wood into small pieces, which are glued and pressed. Since a certain amount of adhesive is used in the production of particle boards, formaldehyde will be released. Compared with solid wood boards and ecological boards, the amount of formaldehyde released by particle boards will generally be larger. If the particles produced by some small factories board, there may also be serious indoor formaldehyde pollution problems. For particle boards produced by some regular manufacturers, they will undergo strict testing before leaving the factory, and the amount of formaldehyde released is within the national standard. Therefore, depending on the economic capacity, if you can choose solid wood and finger-jointed boards, choose better ones. In addition, it is also very important to achieve indoor air quality standards through ventilation.

On the whole, considering the cost performance of particle board, it is not surprising that most custom furniture manufacturers will choose particle board as raw material.

1 thought on “Why most of the custom-made furniture uses particle boards”

Wow, marvelous weblog structure! How lengthy have you been blogging for?

you make running a blog look easy. The overall glance of your website is excellent, as neatly as the content material!

You can see similar here dobry sklep