Why do custom furniture use particle board instead of plywood?

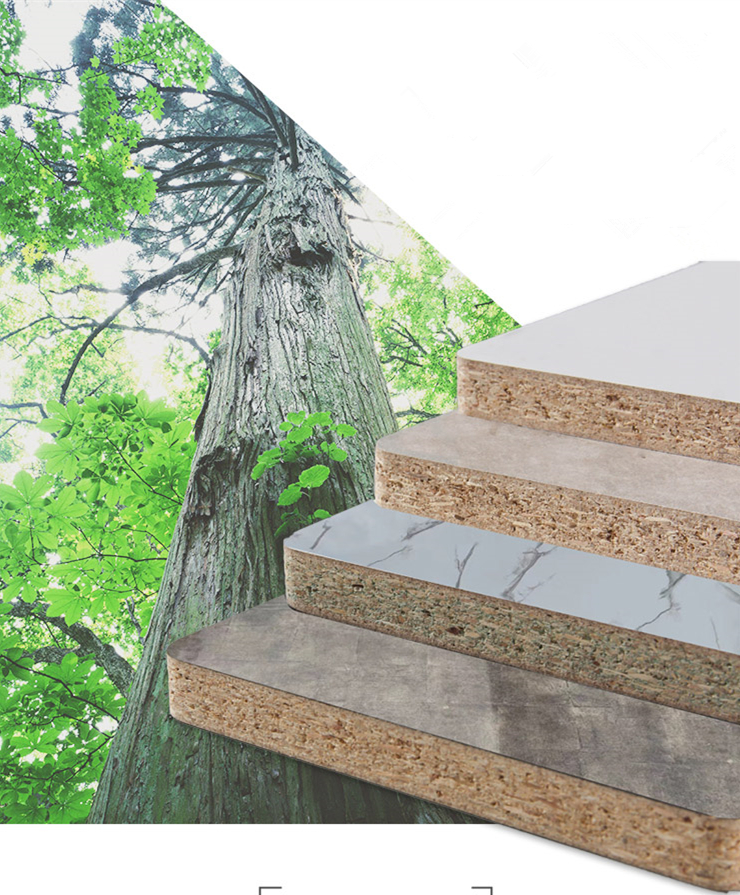

At present, customized furniture has become the first choice for consumers when decorating, and the key factor affecting the quality of customized furniture is the choice of panels. The main home building materials on the market are: particle board (particle board, moisture-proof board), density board (medium fiber board), ecological board (wood board, large core board), multi-layer board (plywood), finger joint board, logs, etc. .

In the market, there are basically well-known brands, and the cabinets are generally made of particle boards. So, why should you choose this way?

particle board is better than density board in crack resistance, gripping force and moisture resistance.

Advantages of particle board Compared with other boards, particle board is better than density board in crack resistance, gripping force and moisture resistance. Although it lacks in waterproof performance, it is three for the current custom cabinets The partition wall on the Heyi fastener is not made on site, so the physical properties of its defects can be ignored.

From the perspective of environmental protection performance,they actually same.

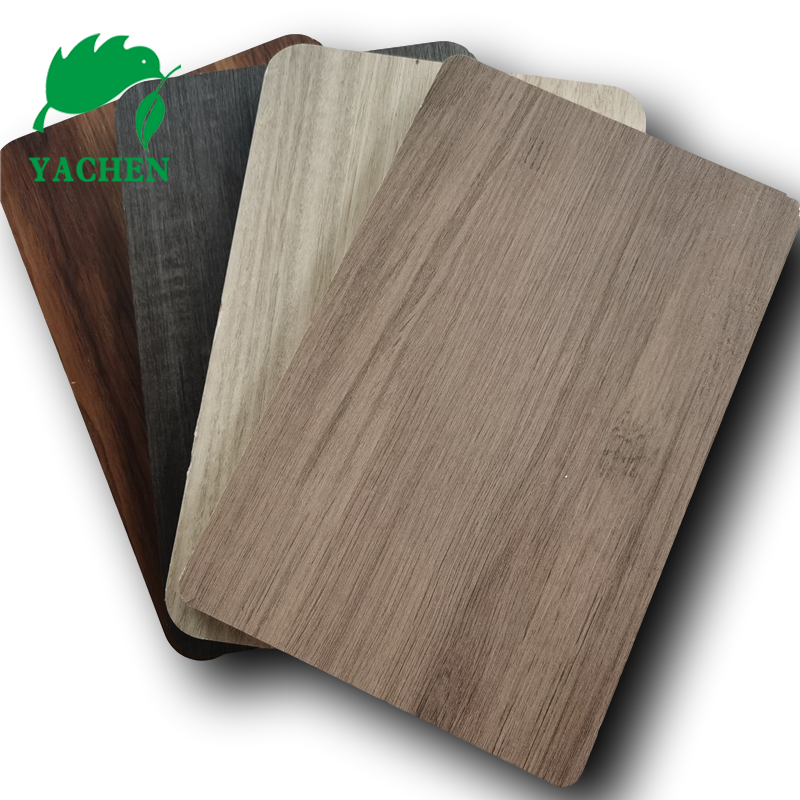

From the perspective of environmental protection performance, many people think that the panels used in custom wardrobes are environmentally friendly, so the wardrobes are also environmentally friendly. We always enter a misunderstanding, not which panel is good, which one is environmentally friendly. All the boards are made of wood, and the formaldehyde content of the wood itself is about 0.1 mg. In fact, the amount of formaldehyde left is actually determined by the quality of the glue used in the production process and the quality of the process control during the production process. produced. At present, there are urea-formaldehyde glue, triamine glue and MDI glue on the market. MDI glue does not contain formaldehyde, which is convenient for large-scale mechanized production. Now most of them are produced by modern series of large machines and assembly lines. The size of the particle board is relatively accurate and the interior is dense. , It is convenient for large-scale mechanized and electronically controlled production, but the dimensional accuracy of the multi-layer board of the ecological board is not enough, especially the interior of the ecological board is not dense, and good equipment cannot be used at all. It is only suitable for some relatively poor equipment and on-site construction. (Note: Particle boards are generally not used in on-site construction, and ecological boards and knuckle boards are often used if the equipment is not good enough).

Particle board is cheaper than plywood

Relatively cheap In the case of the same environmental indicators, the price of particle board is relatively low. As an enterprise, it is for the purpose of profit. When the quality and environmental protection are relatively good, it will definitely choose the relatively cheap one. To sum up, compared with plywood, particle board has great advantages in terms of quality, environmental protection and price, which is why big brands basically choose particle board for their cabinets.