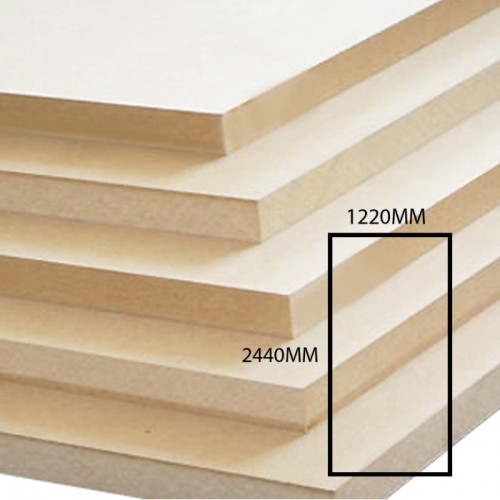

Medium Density Fiberboard (MDF for short) is a new type of board. It is made of high-quality wood fiber, which is processed by high pressure, high temperature and specific chemical agents. The advent of MDF boards has given people more choices in terms of furniture and decoration. In this article, we explore the history of MDF boards, from its origins all the way to the present day.

The origin of MDF boards can be traced back to the 1960s. At that time, the wood resources in Europe began to be exhausted, making traditional wood boards had become an expensive way, and the development of MDF boards was precisely to solve this problem. In 1966, the world’s first MDF boards was manufactured in the United States, and its main use was for the production of indoor furniture. Subsequently, the United States, Canada, Europe and other countries began to gradually promote the production and use of MDF boards.

In the early 1980s, the production of MDF boards was promoted in northern Jiangsu, and in the early 1990s, China also started the production of MDF boards. Since then, with the continuous improvement of technology and the continuous upgrading of processing equipment, MDF boards have been widely used in China. At present, many domestic furniture manufacturers use MDF boards as their main materials, not only because of their high strength, strong moisture resistance, and efficient production process, but also because of their smooth surface and good decorative performance.

The manufacturing technology and application range of MDF boards have been gradually expanded. Now MDF boards are not only used in furniture production, but also in various fields such as architectural decoration, audio, packaging, etc. It is precisely because of the superior function and performance of the MDF boards that it has become an indispensable new type of board, and industry experts often call it “the material of the future”.

MDF boards not only popularize the decoration industry, but also contribute to environmental protection. In order to produce traditional wood panels, a large area of trees needs to be felled, but the production of MDF boards does not require so much wood. The amount of wood required for the manufacture of MDF boards is relatively small, mostly small-radius wood strips, bark, etc., which can reduce wood waste and environmental damage. And because the surface of the MDF boards is smooth and consistent, it will be smoother even during dyeing and paint processing, so its value for environmental protection and green low-carbon development is even more immeasurable.

MDF boards need to pay attention to some matters in production, transportation and use to ensure its quality and safety. We will introduce the precautions for using MDF boards in detail.

Environmental Conditions

The manufacture of MDF boards requires strict environmental conditions, so it is also necessary to maintain appropriate environmental conditions during use and storage. The ambient humidity should be controlled between 8% and 14%. If the humidity is too high or too low, the board may be damaged. Expansion or contraction, causing problems such as cracking. At the same time, direct sunlight and excessive humidity should be avoided.

Physical Damage

The surface of MDF boards may be physically damaged by friction, scratches or impacts. In order to avoid this situation, it is necessary to pay attention to the transportation, handling and installation of MDF boards, and be as careful as possible when moving them. If there is physical damage, it can be repaired by pasting patches.

Soaking and Moisture

The MDF boards cannot be used in an environment soaked in or exposed to water, nor can it be used on a horizontal or inclined surface. Its high water absorption rate may cause the board to deform. In order to avoid deformation of MDF boards, appropriate waterproof materials should be used for treatment, and waterproof measures such as sun visors should be used when necessary to keep their surfaces clean and smooth.

Processing and Application

MDF boards can be cut, engraved, drilled and polished using a variety of processing methods, so they can be custom designed and manufactured as needed. During the application of the MDF boards, care needs to be taken not to bend excessively at the edges, so as not to break the board or cause physical damage.

Hazardous Substances and Safety

MDF boards often contain harmful substances such as formaldehyde. We should try our best to choose environmentally friendly boards that meet the standards. When processing, you need to pay attention to wearing protective equipment, such as masks, gloves, etc., and be careful not to generate shear heat when reinforcing and cutting MDF boards. At the same time, when using MDF boards, you should also avoid contact with irritating odors and food substances.

In short, medium density fiberboard is a very important new building material, which is widely used in furniture, architectural decoration and other fields. When using, we must pay special attention to environmental conditions, physical damage, immersion and moisture, processing and application, harmful substances and safety precautions to ensure the quality and safety of MDF boards. By strictly controlling these precautions, it will help the MDF boards to exert its advantages in multiple application fields for a long time, and at the same time, it can also achieve the goal of environmental protection, green and low carbon.