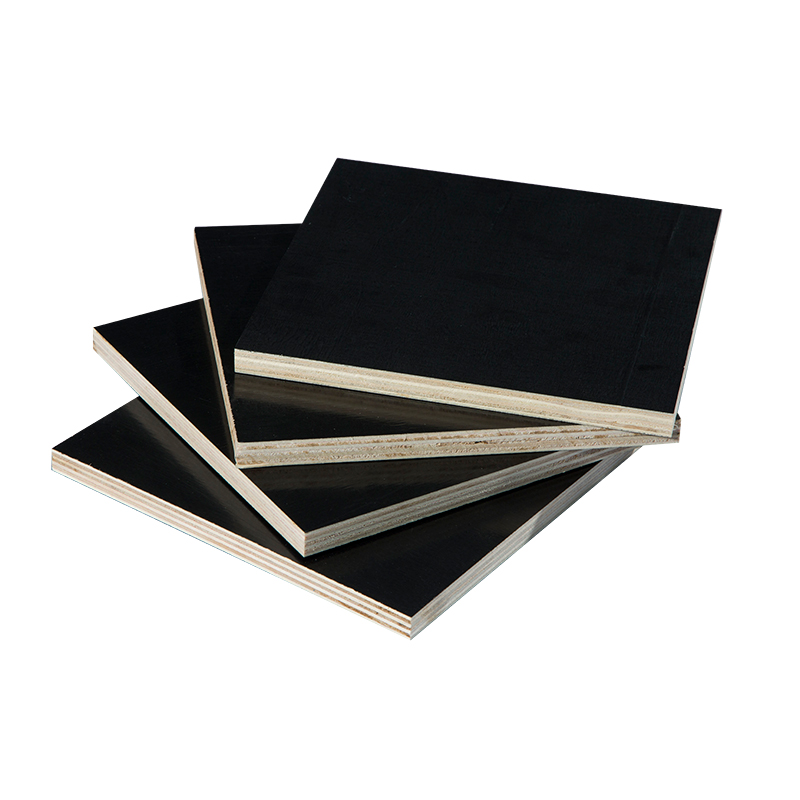

Film faced plywood is a high quality plywood widely used in construction and furniture manufacturing. It is favored for its durability, water resistance and aesthetic advantages. The following is an introduction about Film faced plywood.

First of all, the durability of Film faced plywood is one of its most important characteristics. It is made of cross-stacked multi-layer wood boards, and the direction of each layer of wood grains is perpendicular to each other, which makes Film faced plywood excellent in strength and stability. This structural design makes Film faced plywood able to bear heavy pressure, resist bending and deformation, so it is very suitable for building structures, slabs and floors, etc.

Secondly, Film faced plywood has excellent waterproof performance. Its surface is covered with a strong film, usually imported resin film or phenolic paper film. This film can effectively prevent the penetration of moisture, so that Film faced plywood can be used in humid environments, such as kitchens, bathrooms and various aquatic processing places. This not only enhances the durability of the Film faced plywood, but also facilitates cleaning and maintenance.

In addition, the appearance of Film faced plywood is also one of its attractive advantages. The film-covered surface has a smooth, uniform and beautiful appearance, which can provide high texture for interior decoration, whether as an exterior surface of furniture or as a finishing material for walls and ceilings. In addition, Film faced plywood can also be used for painting or printing to meet different decoration styles and individual needs.

Finally, Film faced plywood is also characterized by easy installation. It is dimensionally stable and very easy to cut and process. This allows builders to install and use Film faced plywood quickly and efficiently, increasing productivity.

Installing Film faced plywood is a relatively simple process. Here are some steps and precautions for installing Film faced plywood:

Preparation: Before you begin installing Film faced plywood, make sure the work area is clean and that the underlying surface is flat, dry and stable. This will ensure that the Film faced plywood will hold securely to the subfloor once installed.

Measuring and Cutting: Use a measuring tool to measure the required dimensions and cut the Film faced plywood to the desired size using appropriate tools such as ruler and saw. Make sure the edges of the cut are straight and flat.

Positioning and marking: Position the Film faced plywood in the desired position according to actual needs, and mark each corner with a pen or pencil. This will help you ensure the correct position of the Film faced plywood when installing.

Pre-drilled and Secured: To prevent the edges of the Film faced plywood from cracking, use a drill to pre-drill holes in each corner. Then, securely secure the Film faced plywood to the underlying surface using appropriate screws or nails. Make sure the screws or nails are fully embedded in the Film faced plywood to ensure a secure fit.

Seams and Smoothing: If multiple pieces of Film faced plywood are to be joined together to form a large covering, ensure that there are suitable seams between adjacent panels. Seams can be filled with sealant to prevent moisture penetration. Finally, smooth the surface of the Film faced plywood with a tool such as sandpaper or a woodworking scraper to make it more even.

Inspection and Adjustment: After the installation is complete, carefully inspect the quality of the Film faced plywood installation. Make sure that each panel is securely fastened and that the surface is flat and free of obvious defects. Make adjustments or repairs if necessary.

To sum it up, Film faced plywood is a high quality plywood that offers durability, water resistance, aesthetic advantages, and ease of installation. It is widely used in the construction industry and furniture manufacturing industry, and can be used in various occasions, such as building structures, decorative materials and furniture making, etc. Film faced plywood meets every need, both in terms of functionality and aesthetics, and offers users a reliable and long-lasting solution.