Building formwork is a kind of frame structure, which is used to protect the supporting structure, so that this kind of formwork can be used more strongly. The decorative materials are determined to be very strong, so that our house can be built stronger, such steel structure engineering formwork is essential. Today, I will introduce the classification of building templates from a professional point of view? What are the main uses of building templates?

What are the classifications of building templates? What are the main uses of building templates?

1) Classification by material:

Building formwork is divided into wood formwork, steel-wood formwork, steel formwork, steel-bamboo formwork, plywood formwork, plastic formwork, FRP formwork, aluminum alloy formwork, etc. according to the materials used.

1. The tree species of the wooden building formwork can be selected according to the actual situation of each region, generally pine and fir.

Due to the large consumption of wood and low reuse rate of wood formwork, in order to save wood, the use of wood formwork should be minimized or not used in cast-in-place reinforced concrete structures. Steel-wood formwork is a stereotyped formwork with angle steel as the frame and wooden board as the panel. The advantage is that it can make full use of short wood and can be used multiple times.

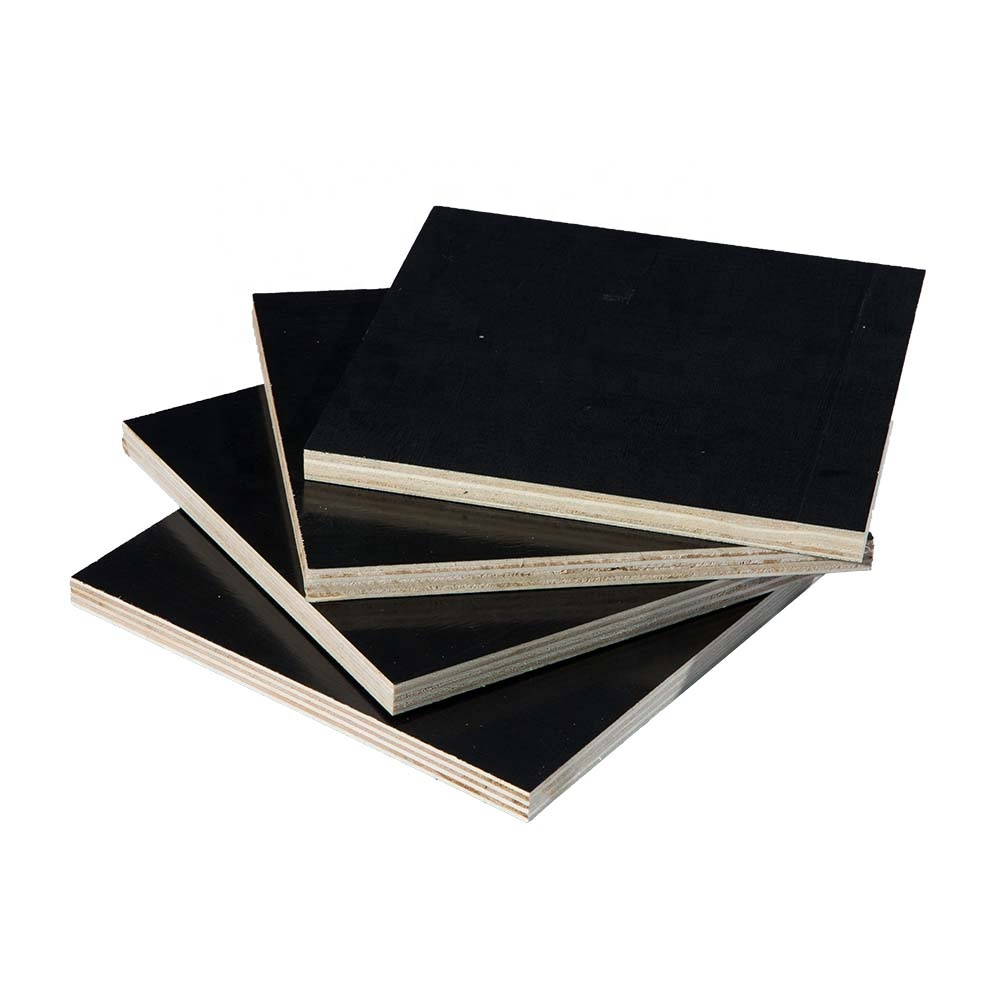

2. The plywood building template is a stereotyped template with plywood as the panel and angle steel as the frame. The plywood is used as the panel, which overcomes the disadvantage of unequal directionality of wood, and has good mechanical performance. This formwork has the advantages of high strength, low self-weight, no warping, no cracking, large plate width and few seams. The steel bamboo formwork is a stereotyped board with angle steel as the frame and bamboo plywood as the panel. The template has high rigidity, is not easily deformed, is light in weight, and is easy to operate.

3. Steel building templates are generally made into shaped templates, which are assembled into various shapes and sizes with connecting components, which are suitable for various structural forms and are widely used in the construction of cast-in-place reinforced concrete structures. Steel formwork has a large amount of investment at one time, but the turnover rate is high. During the use process, attention should be paid to storage and maintenance to prevent rust to prolong the service life of the steel formwork.

4. Plastic formwork, glass fiber reinforced plastic formwork and aluminum alloy formwork have the characteristics of light weight, high rigidity, convenient assembly and high turnover rate, but due to the high cost, they have not been widely used in construction.

(2) Classification by structure type:

Various cast-in-place reinforced concrete structural components have their own characteristics due to their different shapes, sizes and structures, and the structure and assembly methods of the formwork are also different.

According to the type of structure, the building formwork is divided into: foundation formwork, column formwork, beam formwork, floor formwork, stair formwork, wall formwork, shell formwork, chimney formwork, etc.

(3) Classification by construction method

1. On-site assembly and disassembly building formwork: The formwork is assembled on site according to the structural shape, size and space position required by the design at the construction site, and the formwork is removed when the concrete reaches the dismantling strength. The on-site assembly and disassembly formwork is multi-purpose shaped formwork and tool support.

2. Fixed building formwork: formwork for making prefabricated components. The formwork is made on site or in a prefabricated factory according to the shape and size of the components. All kinds of tire molds (soil tire mold, brick tire mold, concrete tire mold) are fixed formwork.

3. Mobile building formwork: With the pouring of concrete, the formwork can move in the vertical or horizontal direction, which is called mobile.