What is plywood?

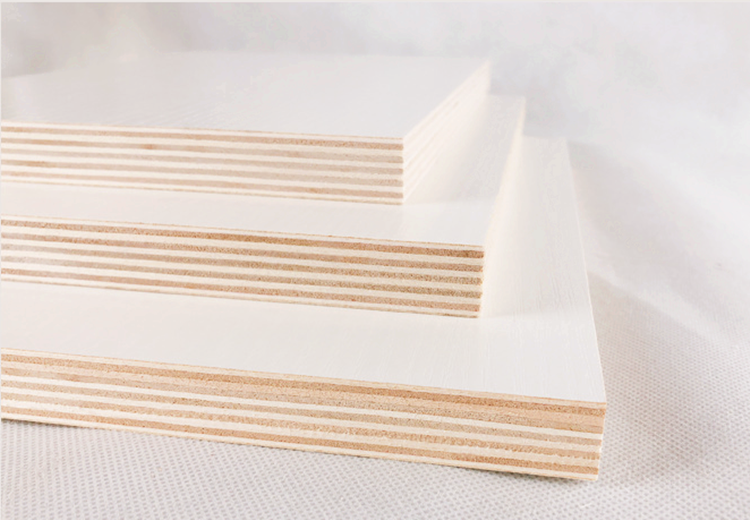

Plywood is a three-layer or multi-layer board-like material that is made of wood sections that are peeled into veneers or sliced into thin wood, and then glued with adhesives. Usually, odd-numbered veneers are used, and adjacent layers of veneers are used. The fiber directions are glued perpendicular to each other.

Plywood is one of the commonly used materials for furniture, and it is one of the three major boards of wood-based panels. It can also be used for aircraft, ships, trains, automobiles, buildings and packaging boxes. A group of veneers are usually assembled and glued together according to the direction of the wood grain of adjacent layers perpendicular to each other. Usually, the surface board and inner layer board are symmetrically arranged on both sides of the center layer or core. The slab made of the veneer after gluing is criss-crossed according to the direction of wood grain, and pressed under heating or non-heating conditions. The number of layers is generally an odd number, and a few have even numbers. The difference in physical and mechanical properties in the vertical and horizontal directions is small. The commonly used types of plywood are three-ply board, five-ply board and so on. Plywood can improve wood utilization and is a major way to save wood.

The usual length and width specifications are: 1220×2440mm, and the thickness specifications are generally: 3, 5, 9, 12, 15, 18mm, etc. The main tree species are: beech, camphor, willow, poplar, eucalyptus and so on.

The basic principle of choosing a plywood

In order to improve the anisotropic properties of natural wood as much as possible, so that the properties of plywood are uniform and the shape is stable, the structure of general plywood must abide by two basic principles: one is symmetry; the other is that the fibers of adjacent layers of veneer are perpendicular to each other. The principle of symmetry is to require that the veneers on both sides of the symmetrical central plane of the plywood should be symmetrical to each other regardless of the nature of the wood, the thickness of the veneer, the number of layers, the direction of the fibers, and the moisture content. In the same plywood, veneers of a single species and thickness can be used, or veneers of different species and thickness can be used; however, any two layers of veneers that are symmetrical to each other on both sides of the symmetrical central plane must have the same species and thickness. The face and back panels are not allowed to be of the same tree species.

To make the structure of plywood meet the above two basic principles at the same time, its number of layers should be odd. Therefore, plywood is usually made into odd-numbered layers such as three layers, five layers, and seven layers. The names of each layer of plywood are: the surface veneer is called the surface board, the inner veneer is called the core board; the front board is called the panel, and the back board is called the back board; in the core board, the fiber direction is parallel to the board It is called long core board or medium board. When forming cavity deck slabs, the front and back panels must face tightly outward.

Classification of plywood

(1) According to the use, it is divided into ordinary plywood and special plywood.

(2) Ordinary plywood is divided into Class I plywood, Class II plywood, and Class III plywood, which are weather-resistant, water-resistant and non-moisture-resistant plywood.

(3) Ordinary plywood is divided into unsanded board and sanded board according to whether the surface is sanded or not.

(4) According to the tree species, it is divided into coniferous wood plywood and pavilion leaf wood plywood.

How to choose plyood

In the production of plywood, many varieties of designs and colors are derived, the most important of which is to paste a thin layer of decorative veneer veneer on the surface of the original plywood, called decorative veneer veneer plywood, referred to as decoration in the market. board or veneer.

It is worth noting that common veneers are divided into natural wood veneer veneers and artificial veneer veneers. Natural wood veneer is a veneer veneer made of precious natural wood through planing or rotary cutting. Artificial veneer is made of veneer by rotary cutting of relatively cheap logs, which is pressed into wooden squares by a certain process of glue, and then sliced to make decorative veneer with beautiful patterns.

Usually the veneer attached to the natural wood veneer veneer is often a tree species with good pattern and high value, such as cypress, oak, rosewood, ash, etc. But it should be stated in the trade name, such as “cypress veneered plywood”, or “ash sliced plywood”, or “cherry wood veneer”. The “veneer”, “slicing” and “plywood” in several ways reflect the basic characteristics of “plywood”. However, it cannot be abbreviated as cypress three-plywood, ash three-plywood, etc., because these abbreviations refer to the panels and bottom plates of plywood being made of cypress or ash. Another issue is the increasing amount of veneer-made furniture that, although it has the appearance of wood grains like “cypress,” is generally made of other woods that shops now refer to as “cypress.”

Selection points about plywood

1) Select plywood of different types, grades, materials, decorations and formats according to the nature of the project, the location of use, environmental conditions and other factors.

2) Plywood veneered with precious wood sliced veneer should be used for decoration.

3) The plywood used for building interior decoration shall comply with the provisions of GB50222 “Code for Fire Protection Design of Building Interior Decoration”.

4) Type I or Type II plywood should be considered for concealed parts that may be damp and places with high waterproof requirements, and Type I plywood should be used for plywood used outdoors.

5) Transparent varnish (also known as varnish) should be used for panel decoration to retain the natural color and texture of the wood surface. The choice of panel material, pattern and color should be emphasized; if the pattern and color of the panel do not need to be considered, it should also be reasonable according to the environment and cost Select plywood grade and category.