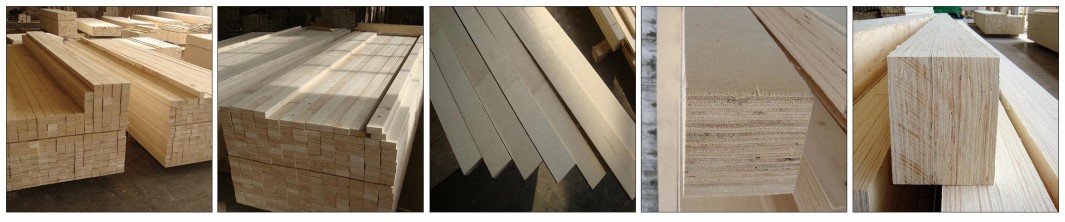

LVL lumber structural features.

High strength, high toughness, good stability and accurate specifications, 3 times higher than solid sawn timber in terms of strength and toughness.

The product has the advantages of being highly environmentally friendly, waterproof, fireproof, anti-corrosion, insect-proof and fumigation-free.

LVL lumber product parameters:

| product name | lvl |

| core material and direction | peeing veneer, poplar, pine, combi, eucalyptus, birch, meranti, okoume, other hardwood, all layers same direction (lvl), or the second layers from the face & back are different direction from other layers (lvb); |

| size | 1220*1220mm or 500*5200mm, most occasion according to inquiries;upon to request |

| thickness and tolerace | 12mm~45mm; +/-0.5mm; |

| surface & treatment | peeling poplar face & back |

| glue | phenolic (phenolic wbp glue, phenolic glue), melamine wbp glue(muf, mf, melamine glue); |

| leading time | within 30 days |

| usage | package/industry, construction, furniture & handicraft, wooden house; |

| capacity | 10000cbm per month; |

| certification | ce,carb p2,fsc,iso |

Features of LVL lumber:

1、It can disperse and stagger the defects such as scars and cracks of the logs, and according to the test, the strength and toughness are 3 times higher than that of solid wood, which makes it stable in quality, uniform in strength and low in material variability;

2、Size can be adjusted arbitrarily, not affected by the shape and defects of the original wood, any size within 8 meters in length, any size within 1.3 meters in width, any thickness within 300 MM, can be customized according to customer requirements, any choice of size, high utilization rate;

3、Processing and wood like, can be sawed, planed, chiseled, tenoned, nailed, etc.;

4、It is insect-proof, anticorrosive, fireproof and waterproof, mainly because of the corresponding pretreatment or special adhesive used in the production process;

5, has a strong seismic performance and shock absorption performance and can resist the fatigue damage generated by the cyclical force;

6、Green and pollution-free, using environmentally friendly adhesives in the production process.

Reviews

There are no reviews yet.