China MDF suppliers

Yachen is one of the best MDF board manufacturers. We can offer reliable quality and competitive prices in the processing of plywood and oriented strand board as well as domestic plywood. We can produce high density fiberboard, medium density fiberboard, low density fiberboard, etc. For details, please consult us and get the mdf board price

Yachen: one of the best MDF board manufacturers in China

MDF can be divided into: E0, CARB P2, E1, E2 grade MDF according to formaldehyde content

According to the density, MDF can be divided into: low density board, medium density board, high density board;

MDF can be used for furniture, modeling, milling and engraving;

High-density boards are mainly used as floor substrates and templates.

MDF can be divided into: moisture-proof MDF, fire-resistant MDF, ordinary MDF, waterproof MDF according to its use.

MDF board manufacturer

Yachen is a professional MDF panel maker can produce MDF 18mm maker as well as 1-30mm MDF, waterproof mdf, fire resistant mdf, mdf panels for walls and mdf 4×8. That’s why we can offer you competitive quality MDF with the most affordable MDF board prices.

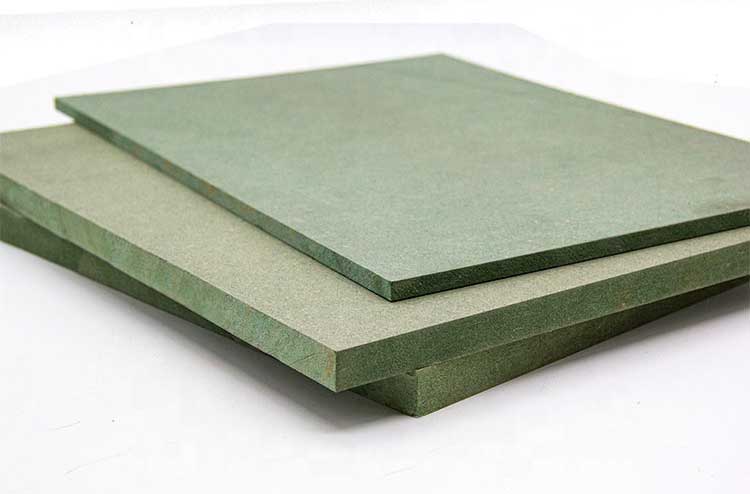

moisture resistant green mdf

Green MDF is a moisture-proof MDF, which is a green moisture-proof factor added in the process of MDF production.

MDF production line

MDF board manufacturer Our products are exported to 80 countries, 30+ production lines serve 1000+ customers, and are deeply favored and praised by customers

yachen: your leading MDF manufacturer

Yachen is one of the manufacturers engaged in the production and manufacture of panels in China. We offer a one-stop solution for plywood and osb panels.

Yachen can oem osb 6mm, osb 8 mm, osb board 9mm, osb 10mm, 11mm osb, osb 12mm, osb 18mm, osb 22mm, osb 20mm, osb 25mm, osb plywood 4×8 for you.

Some customers may choose osb 18mm because it has better optical visibility and better scratch resistance.

In advance, WeProFab can add an ultra-abrasive coating to your polycarbonate windscreen, which can significantly improve the durability of plastic windscreens.

As an ISO 9001 certified manufacturer of osb plywood, yachen has strict control over the manufacturing process.

In short, yachen is a one-stop solution for osb plywood manufacturers. We can supply you with osb 6mm, osb 8 mm, osb board 9mm, osb 10mm, 11mm osb, osb 12mm, osb 18mm, osb 22mm, osb 20mm, osb 25mm, osb plywood 4x so you can focus on how to create value for your customers. Send us an enquiry today; we will provide you with the perfect product.

Yachen MDF makes your brand soar

MDF product configuration parameters

| Product: | Melamine MDF |

| Thickness: | 6mm,9mm,12mm,15mm,16mm, 18mm,21mm,25mm |

| Size: | 1220x2440mm |

| Glue: | MR,WBP Melamine,Phenolic. |

| Surface: | Melamine paper in white,black,solid color, wood grain and other design as request. |

| HPL papar in white,black,solid color, wood grain and other design as request. | |

| Surface Treatment | High glossy, Matt, UV coating or as request. |

| Core: | Raw MDF board, poplar or pine |

| Density | 650-830kg/cbm |

The production plant of the relevant MDF

Yachen has complete competence in the manufacture of OSB sheets and we can show you how to combine the right features into your product according to your final application.

MDF gluing process

MDF paving

MDF preload

MDF hot pressing

MDF polishing

MDF crop

MDF polishing

MDF quality inspection

A collection of MDF product problems

Contents

What is MDF board?

The full English name of mdf board is DensityFiberboard, abbreviated as mdf, referred to as medium fiberboard. A man-made board made of wood fiber or other plant fiber as raw material, after crushing, fiber separation, drying, applying urea-formaldehyde resin or other suitable adhesive, and then hot pressing. Its density is generally in the range of 500-880 kg/m3, and its thickness is generally 5-30 mm.

A kind of medium density fiberboard (man-made board), the logs are degreased and peeled, pulverized into wood chips, and then formed by high temperature and high pressure, and the density is very high, so it is called MDF. Its surface is often affixed with trimer hydrogen ammonia or veneer and other finishes.

Advantages of MDF sheet

1. Excellent physical properties, uniform material, no dehydration problem, no moisture deformation;

2. The trimerized hydrogen ammonia finish on the surface has the characteristics of moisture-proof, anti-corrosion, wear-resistant, high-temperature resistance, etc.

No post-processing is required, and the formaldehyde content is low.

3. Since all the raw materials are very fine wood powder, from the perspective of moisture resistance, if a piece of MDF is soaked in water, it will expand like bread.

What are the classifications of MDF?

1. Low density Name: soft fiberboard

(1) Density standard: the density is below 0.4g/cm3

Weight and other exchange: equivalent to less than 400KG per cubic meter

(2) Material characteristics: light weight, large porosity, good heat insulation and sound absorption,

(3) Board characteristics: After special treatment, lightweight fiberboard with more pores can be obtained, which has adsorption properties and can be used to purify the air.

(4) Product use: It is mostly used as a covering material inside public buildings.

2. Medium Density Name: Medium Density Fiberboard

(1) Density standard: between 0.4g/cm3-0.8g/cm3 (generally about 0.7g/cm3)

Weight and other exchange: equivalent to 400KG-800KG per cubic meter

(2) Material characteristics: uniform structure, moderate density and strength, and good reworkability.

(3) Product use: The product has a wide range of thickness and has a variety of uses, such as furniture materials, TV shell materials, etc.

3. High Density Name: Hardboard

(1) Density standard: the density is above 0.8g/cm3

Weight and other exchange: more than 800KG per cubic meter

(2) Material characteristics: heavy quality, difficult to process

(3) Product use: The product thickness range is small, and it is mostly used in construction, ships, vehicles, etc.

When buying MDF, you should touch the surface of MDF with your hands. The quality of MDF with a smooth surface is good. If it feels astringent, it means that the processing is not in place, and the hard and brittle board must be an inferior product.

Disadvantages of MDF

Smooth and flat surface: Because the MDF is made of fine particles under heating and pressure, the surface is very smooth.

The material is fine: the material is very fine, and it is made of resin, viscose, etc., so the material is fine.

Stable performance: the surrounding material density is the same and therefore very stable.

Easy to decorate the surface: all kinds of paints and coatings can be used for surface decoration of MDF.

Disadvantages of MDF

MDF is composed of binder (formaldehyde) and wood powder. Most of the MDF in China has a serious formaldehyde content exceeding the standard. MDF is a man-made board. The harm to the human body is that the board contains harmful chemicals such as methanol. In addition, a lot of glue must be added in the production of high-density boards. These glues contain formaldehyde, and the release of formaldehyde is harmful to the human body. harmful.

The MDF has poor moisture resistance, and the rainwater is easy to expand and foam, and the paint surface is delaminated.

7 major features of mdf board

1. The internal structure is uniform, the density is moderate, the dimensional stability is good, and the deformation is small.

2. The physical and mechanical properties such as static bending strength, internal bonding strength, elastic modulus, board surface and board edge holding screw force are better than particleboard.

3. The surface is smooth and smooth, which is convenient for secondary processing. It can be pasted with rotary cut veneer, sliced veneer, painted paper, impregnated paper, and can also be directly painted and printed for decoration.

4. The medium density fiberboard has a larger width, and the thickness of the board can also be changed in the range of 2.5~35mm, and the production can be organized according to different purposes.

5. Good machining performance, sawing, drilling, tenoning, groove milling, sanding and other processing properties are similar to wood, and some are even better than wood.

6. It is easy to carve and mill into furniture parts of various profiles and shapes. The processed special-shaped edges can be directly painted and other finishing treatments without sealing the edges.

7. Chemicals such as water repellent, fire retardant and preservative can be added in the production process of MDF to produce MDF for special purposes.

MDF Furniture Maintenance

1. The surface of the furniture must be wiped with a clean soft cloth. It is best to use special furniture wax regularly for maintenance, once a month.

2. Furniture electroplating hardware should be kept dry and clean, and often wiped with a soft dry cloth to keep its luster and no rust.

3. It is not advisable to hit the surface with heavy and hard objects or directly cut things on the surface to prevent damage to the surface of the furniture, and do not push the furniture hard on the ground.

4. Try to avoid children jumping and playing on the furniture, so as not to damage the furniture supporting structure.

5. Pay attention to the ground level when placing.