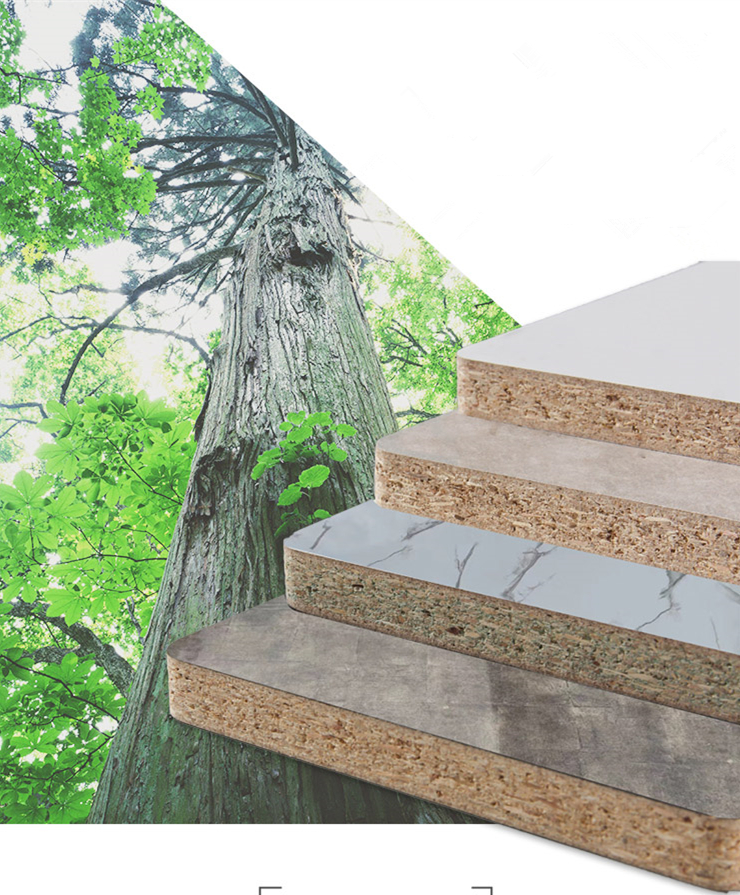

Particleboard, also known as chipboard, is a type of engineered wood panel made from wood particles or other lignocellulose material bonded together with an adhesive under high pressure and temperature. It is a versatile and cost-effective alternative to traditional solid wood and is widely used in the construction, furniture, and packaging industries. In this article, we will discuss the history, production process, and applications of particleboard.

I. History of Particleboard

Particleboard was first invented in Germany in the early 20th century and was initially used for insulation purposes. In the 1950s, it gained popularity as a building material due to its affordability and versatility. The use of particleboard increased rapidly in the 1970s and 1980s, especially in the furniture industry, where it was favored for its uniformity and stability, as well as its lower cost compared to solid wood. Today, particleboard is a commonly used material in many industries and continues to be developed with new technologies and materials to meet the demands of various applications.

II. Production Process of Particleboard

The production process of particleboard mainly consists of the following steps:

- Raw Material Preparation: The timber is chopped into small pieces, and bark and other debris are removed to produce wood chips.

- Particle Sizing and Drying: The wood chips are passed through machines that crush and sieve them to achieve a uniform particle size. The particles are then dried to remove excess moisture.

- Resin Application: Resins such as urea-formaldehyde, melamine-urea-formaldehyde, or phenol-formaldehyde are mixed with the dried particles.

- Panel Formation: The resin-coated particles are placed into a mold and compressed under high heat and pressure. The heat melts the resin and acts as a bonding agent to hold the particles together.

- Grinding and Finishing: After pressing, the panel is cut to size, sanded, and refined to achieve a smooth finish.

III. Applications of Particleboard

Particleboard is a versatile, economic, and eco-friendly material that has a wide range of applications. It is commonly used in the following industries:

- Furniture Industry: Particleboard is widely used in the furniture industry for making bookshelves, bed frames, tables, and chairs. It is ideal for manufacturing furniture due to its cost-effectiveness, dimensional stability, and predictability.

- Construction Industry: Particleboard is used as subflooring, underlayment, roofing and wall sheathing, suspended ceilings, and door cores in construction and other building applications. It is lighter in weight compared to traditional building materials, making it easier to transport and cut, and is more cost-effective than other high-performance materials.

- Packaging Industry: Particleboard is used as a material for transport packaging, especially for heavy or bulky products. It can also be used as a pallet block, edge protector, or other components in packaging.

IV. Conclusion

Particleboard is an engineered wood panel that has many benefits, including affordability, versatility, and eco-friendliness. Its production process is relatively simple and produces a uniform, stable material that can be used in various applications. Particleboard has a bright future due to its cost-effectiveness and continuing technological advancements that will improve its performance in different settings.