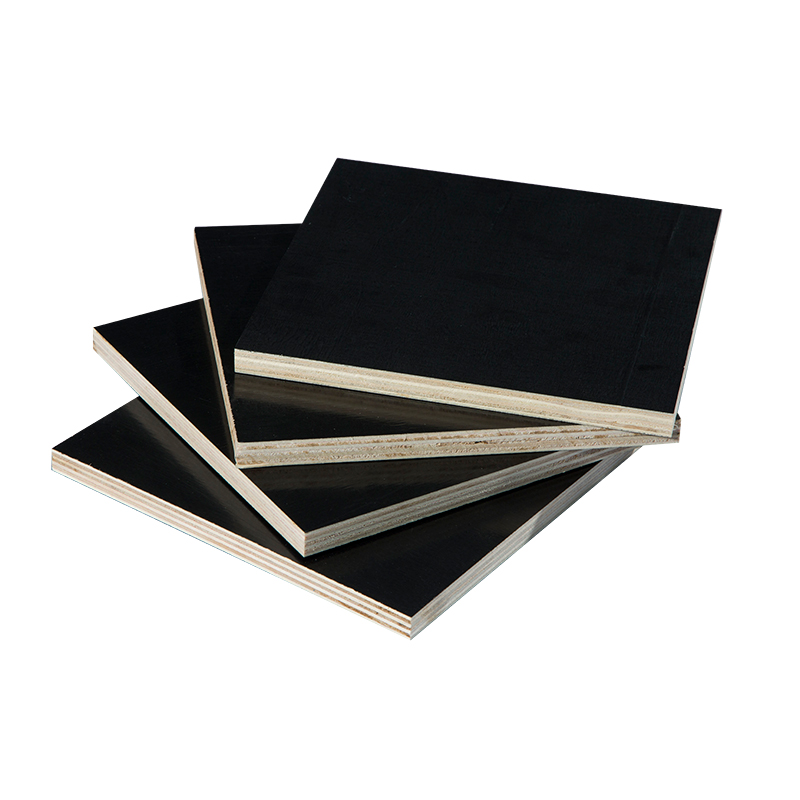

Special type of plywood widely used in construction and decoration fields. It is made of high-quality plywood wood as the base material, and is coated on both sides with a layer of tough and durable membrane material, usually a red or black phenolic resin membrane.

Film faced plywood relies on the unique characteristics of film materials and has the following significant advantages:

Durability: The membrane material forms a hard protective layer on the plywood surface, which can effectively resist impact, abrasion and chemical corrosion. This allows the film faced plywood to be used for a long time without being easily damaged, extending its service life.

Waterproof: The membrane material has excellent waterproof properties and can prevent moisture from penetrating into the interior of the plywood, thereby maintaining the stability and strength of the plywood. This makes film faced plywood particularly suitable for construction projects that require waterproofing, such as cement formwork.

Surface Quality: Film faced plywood’s film material provides a smooth, flat surface that produces a high-quality finish. This makes it ideal for use as templates and moulds, as well as decorative applications where a premium appearance is required.

Easy to clean: The smooth surface of the membrane material is not easily contaminated by dust, oil and other debris, so film faced plywood is easier to clean and maintain. Simply wipe with a damp cloth to restore its shiny appearance.

Versatility: film faced plywood can be customized according to the needs of different projects such as thickness, size, color, etc. This makes it suitable for a variety of interior and exterior decoration and construction purposes, including building formwork, wall coverings, furniture making, and more.

In addition to the advantages mentioned above, Film faced plywood has some other features and advantages:

High strength: Film faced plywood takes advantage of the characteristics of plywood and is reinforced through multiple layers of glue, giving it excellent strength and stability. This means it can withstand heavy pressure and resist deformation, making it suitable for applications that require a high degree of load-bearing, such as beams, columns and floor slabs.

Save time and costs: The waterproof nature of Film faced plywood reduces wear and tear during construction and maintenance costs. Because its surface is smooth and flat, it can reduce the repair time during construction and improve work efficiency.

Environmentally friendly: The glue material of Film faced plywood mainly uses phenolic aldehyde resin, which complies with environmental standards and is harmless to indoor air quality. At the same time, there is no need to use any harmful substances during the gluing process, making it consistent with the requirements of sustainable development.

Easy to Cut and Process: The plywood substrate of Film faced plywood has good cutability and processing properties and can be cut, punched and cut according to specific needs. This allows it to be flexibly applied to a variety of projects that require customized processing.

Good thermal isolation: Film faced plywood’s film material has high thermal isolation performance, which can prevent heat conduction and reduce heat loss. This is very important in structures and building materials where thermal insulation properties are required.

To summarize, Film faced plywood is a versatile plywood that has gained widespread use due to its durability, water resistance, high strength and ease of processing. Whether in the field of construction, renovation or furniture making, Film faced plywood is a reliable choice that can meet the needs of a variety of projects.

Film faced plywood is a versatile building material that has a wide range of applications in a variety of projects. Here are some common application areas:

Construction formwork: The most common application of Film faced plywood in construction projects is as formwork. It is able to withstand the weight and pressure of the concrete, maintains the stability of the formwork, and prevents moisture from penetrating inside the formwork due to its waterproof properties. The smooth surface of Film faced plywood produces a high-quality concrete surface that guarantees building quality after construction.

Wall facing: Film faced plywood can also be used as a wall decoration material. The coating material on its surface is durable and waterproof, protecting the wall and enhancing its appearance. Film faced plywood is also able to handle different climatic conditions and humidity indoors and outdoors, making it an ideal wall covering.

Furniture Making: Film faced plywood is also widely used in furniture making due to its beautiful appearance and durability. It can be used to make various furniture such as desks, chairs, cabinets, etc. Its smooth surface can also be decorated and painted to meet personalized needs.

Decorative decorative panels: Film faced plywood is often used as decorative panels in interior decoration, such as floors, partitions, ceilings, etc. It provides a durable surface while also bringing warmth and quality to interior spaces.

Stage Construction: The strength and stability of Film faced plywood make it ideal for stage and performance venue construction. It is capable of withstanding heavy equipment and large numbers of people, while being customizable in shape and size as needed.

Carriage and Container Lining Materials: Film faced plywood’s water resistance and durability make it an ideal material for car and container linings. It protects goods from moisture and impact while being able to withstand the stress during transportation and stacking.

In addition to the above applications, Film faced plywood can also be used in shipbuilding, facade decoration, outdoor construction and other fields. Its versatility and adaptability make it one of the indispensable materials in the construction and decoration industries.