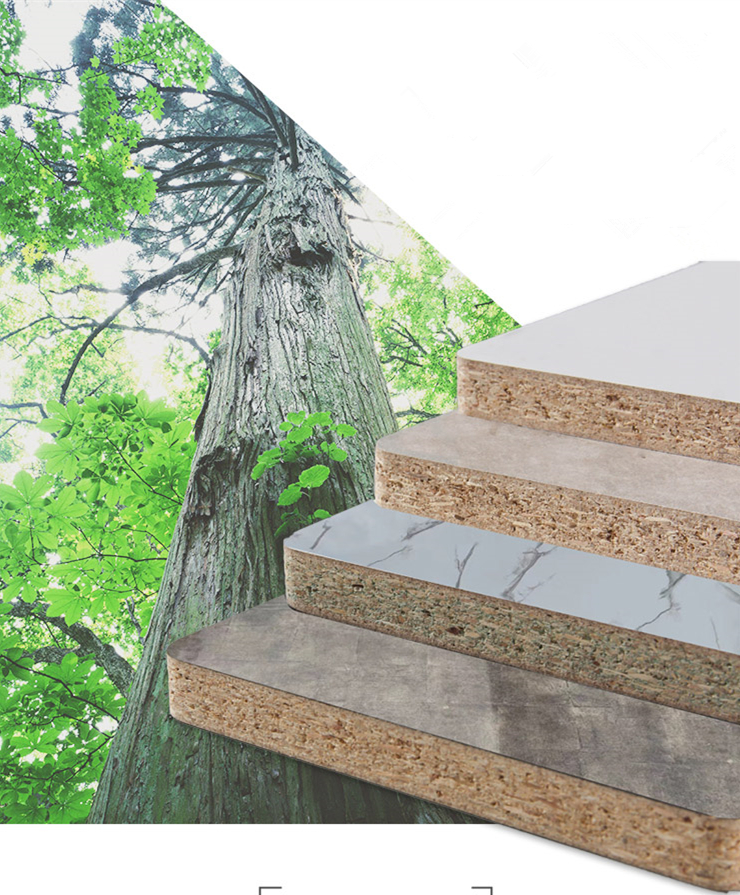

Particle Board is a man-made board made of wood chips, wood chips and synthetic resin binders. It is an affordable and versatile material widely used in furniture manufacturing and architectural decoration. This article will introduce the characteristics, advantages, disadvantages and application fields of particleboard in detail.

First, the characteristics of particleboard:

Variety of materials: The raw materials of particleboard can include various wood chips and wood chips of different tree species, so different wood species can be selected according to needs, such as pine, birch, etc.

High strength: Particleboard is made of a large number of wood particles bonded together by adhesives to form a tough structure, so it has high strength and stability.

Flat surface: The surface of particleboard is relatively flat, suitable for surface coating, veneer or covering to achieve different decorative effects.

Strong machinability: Particleboard is easy to cut, drill and carve, so it can meet different craft and design needs.

Environmentally friendly and sustainable: Particleboard is made from waste wood or by-products of wood processing, using renewable resources, helping to reduce wood waste and protect forest resources.

Second, the advantages of particleboard:

Affordable: Particleboard is less expensive than solid wood and plywood, making it an affordable option, especially for large-scale production and low-cost projects.

Easy to process: Particleboard is soft and easy to cut, drill and shape to meet the needs of different sizes and shapes.

Flat surface: The surface of the particle board is flat and can be directly painted, veneered or covered, so that it has a good decorative effect.

Portable and portable: Compared with solid wood boards and plywood, particle boards are lighter in weight and easy to carry and install.

Third, the disadvantages of particleboard:

Strong water absorption: Particleboard is easy to absorb water, so it is easy to swell and deform in a humid environment, and it is necessary to avoid prolonged exposure to water sources.

Poor elasticity: Particleboard is relatively hard and less elastic, prone to breakage or breakage, and requires care to avoid excessive loads and impacts.

Low durability: Compared with solid wood boards and plywood, particle boards have low durability and are prone to moisture, corrosion and wear, so special attention should be paid to their use and maintenance.

In order to ensure the safe and effective use of particle board, here are some things to pay attention to when using particle board:

1. Choose particleboard with reliable quality: When purchasing particleboard, you should choose products with reliable quality. A good quality particleboard should have an even grain and a smooth surface. Check the thickness and strength specifications of the particleboard to make sure it meets your needs.

2. Keep the particleboard dry: Particleboard is composed of wood chips and adhesives, if exposed to excessive humidity, it will cause the particleboard to deform, mold or lose its strength. Therefore, before using the particleboard, make sure it is in a dry environment and protected from moisture during storage and transportation.

3. Reasonable use of size: according to the needs, choose the appropriate particleboard size. If a larger area is required, multiple pieces of particleboard can be used to splice. Pay attention to the size of the particleboard to match the size and requirements of the construction site to avoid excessive waste or insufficient size.

4. Install the particleboard correctly: Before installing the particleboard, make sure that the foundation is flat and firm. Accurate measurements and markings with professional tools to ensure the exact placement of the particle board during construction. Secure the chipboard with suitable glue or nails to ensure its stability.

5. Keep it properly maintained: Particle boards require regular maintenance to maintain their beauty and longevity. Clean the particleboard surface regularly and avoid using acidic or alkaline cleaners. If the particle board is found to be bumped, scratched or deformed, it should be repaired or replaced in time.

6. Pay attention to fire safety: Particleboard is a kind of wooden material and is flammable. Fire safety measures need to be taken into account when installing particleboard. Keep the area of use well ventilated and avoid using open flames close to the particleboard, such as smoking, gas stoves, etc.

7. Properly dispose of waste: After the particleboard is used, the waste should be disposed of correctly. Properly dispose of particleboard waste according to local waste management regulations to avoid environmental pollution.

When using particleboard, choosing a product of reliable quality, maintaining a dry environment, using size wisely, installing it correctly, maintaining it regularly, paying attention to fire safety, and disposing of waste properly are all important considerations to ensure the safe and effective use of particleboard. Following these guidelines will help you get the most out of your particleboard and ensure quality construction.