China commercial plywood manufacturer

Yachen is one of the best commercial plywood manufacturers. Our full capabilities in plywood and home plywood processing ensure precise tolerances as well as competitive prices. We can produce 6mm, 8 mm, 9mm, 10mm, 11mm , 12mm, 18mm, 22mm, 20mm, 25mm, plywood 4×8, etc. Send us your drawings today!

Yachen: Your premier commercial plywood manufacturer

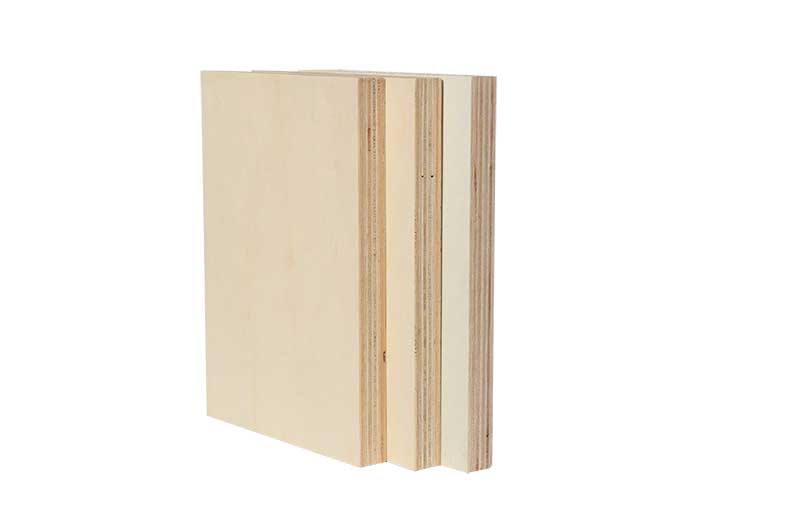

commercial plywood,The main product features of commercial plywood: poplar or hardwood core, MR glue most used,you can choose MDI glue,WBP glue also, Okoume or poplar surface (or bintangor or something), used for furniture and packaging, our price is cheap and of course with our best quality.

commercial plywood product configuration parameters

Product: Commercial Plywood

Thickness: 2-40mm

Size: 1220x2440mm,1250x2500mm,1525x3050mm,1830x3660mm and other custmized size.

Core: Poplar, hardwood, Birch, Pine, Combi, Eucalyptus.

Surface: Poplar,Birch,Pine,Okoume,Bintangor, Pencil Cedar,etc.

Surface Grade: C/D,D/E,E/F,BB/CC

Glue: MR, WBP Melamine, Phenolic.

The production plant of the relevant Commercial Plywood

Yachen has complete competence in the manufacture of OSB sheets and we can show you how to combine the right features into your product according to your final application.

plywood veneer

cold pressing process

hot pressing process

crop trim

yachen: your leading commercial plywood manufacturer

Yachen is one of the manufacturers engaged in the production and manufacture of panels in China. We offer a one-stop solution for plywood and osb panels.

Yachen can oem osb 6mm, osb 8 mm, osb board 9mm, osb 10mm, 11mm osb, osb 12mm, osb 18mm, osb 22mm, osb 20mm, osb 25mm, osb plywood 4×8 for you.

Some customers may choose osb 18mm because it has better optical visibility and better scratch resistance.

In advance, WeProFab can add an ultra-abrasive coating to your polycarbonate windscreen, which can significantly improve the durability of plastic windscreens.

As an ISO 9001 certified manufacturer of osb plywood, yachen has strict control over the manufacturing process.

In short, yachen is a one-stop solution for osb plywood manufacturers. We can supply you with osb 6mm, osb 8 mm, osb board 9mm, osb 10mm, 11mm osb, osb 12mm, osb 18mm, osb 22mm, osb 20mm, osb 25mm, osb plywood 4x so you can focus on how to create value for your customers. Send us an enquiry today; we will provide you with the perfect product.

A collection of Commercial Plywood product problems

What is the multi-layer board?

The multi-layer board is a three-layer or multi-layer board material made of wood segments that are cut into veneers or sliced into veneers, and then glued with adhesives.

1. Multi-layer board, also known as plywood, is a common furniture material. Generally, a single odd-numbered layer is used to bond adjacent veneers to each other in the longitudinal direction. Usually, its crown plywood is symmetrical with the inner plywood on either side of the central layer or core. Common three plywood, five plywood and so on. Plywood can effectively improve the utilization rate of wood and is an important material saving method.

2. Advantages of multi-layer boards: It is better to use multi-layer boards of all eucalyptus. The natural characteristics of eucalyptus are high density, high compressive strength, not easy to crack, deform, and will not expand and dry under various temperatures. And other issues. Environmental protection: the multi-layer boards are all natural wood, which can adjust the indoor temperature and humidity, and is easy to install.

3. The manufacturing method of the multilayer board is usually to use the inner layer pattern and then use the printing and etching method to make a single-sided or double-sided bottom plate. And put it into the designated interlayer, heat, pressurize, bond, and the final punching process is the same as the electroplating process of the double-layer board. These basic manufacturing processes have not changed much compared to the process in the 1960s, but with the development of materials and process technology, such as: bonding technology, solving the glue slag produced when drilling, film improvement), so The properties of the attached multilayer sheets are also more diverse.

Expanded multi-layer board is one of the commonly used materials in furniture processing enterprises, and it is a kind of artificial board.