Plywood is a commonly used building and interior finishing material with a history dating back to the early 19th century. The emergence and development of plywood is inseparable from people’s demand for wood and technological innovation. The following is a detailed introduction to the historical origin of plywood.

1. The invention of plywood

Plywood is a board made of glued veneers or wood chips. The earliest plywood was invented by Sprengle in the United States, who in 1905 bundled the wood chips produced during the machining process to form the first plywood.

However, the plywood produced by Spreger is not strong enough and will oxidize and rot after a while. Subsequently, people tried to use phenolic resin instead of the original glue, which made the plywood stronger and more durable. In 1928, the Finnish Conscience Dumont (Ligno-Duropal) company further pushed the plywood production technology to a certain height, making plywood widely used.

2. Development and application of plywood

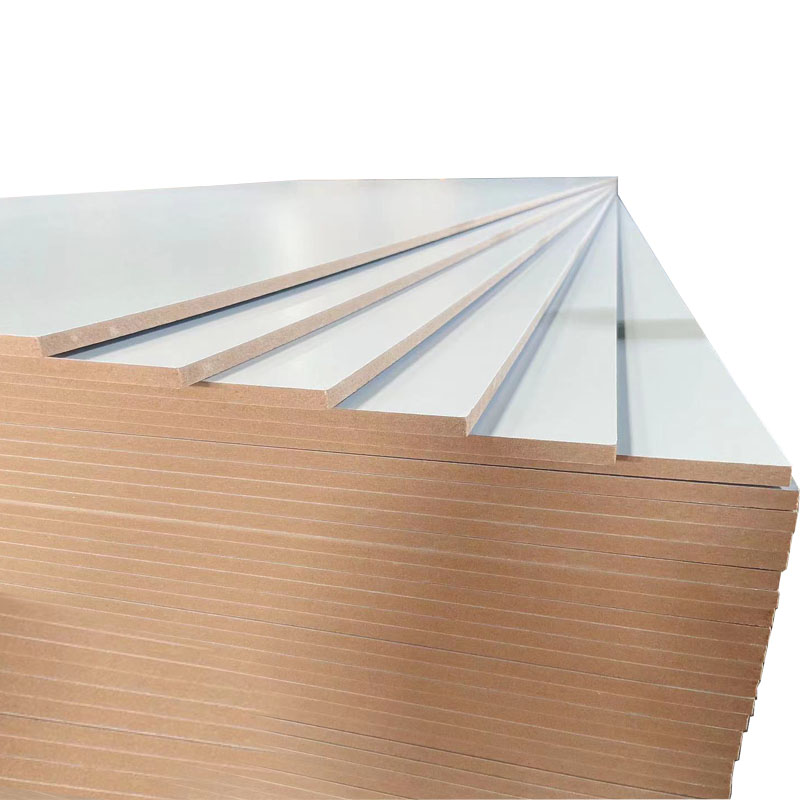

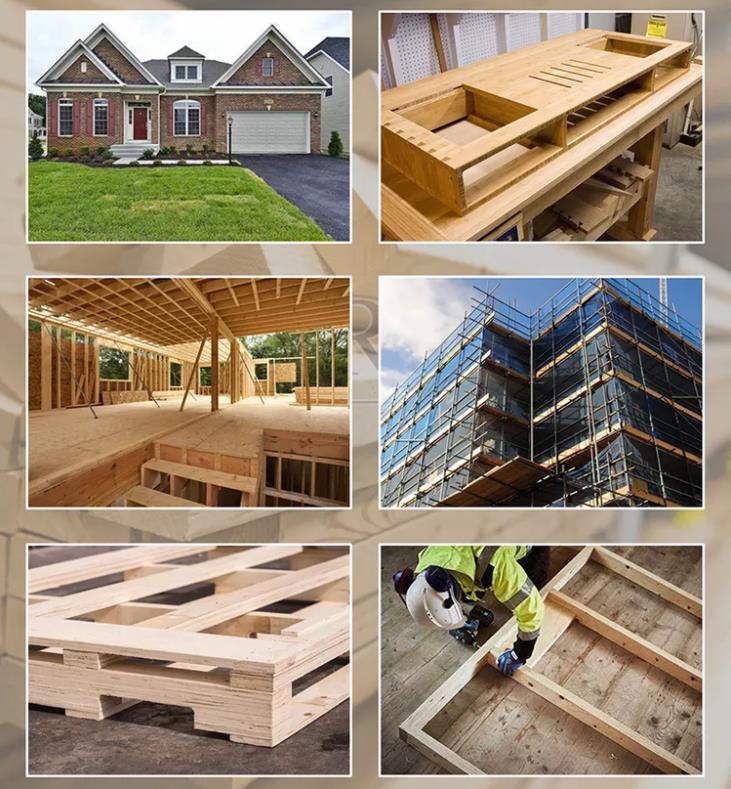

In the 1950s, plywood technology began to be widely used in Europe. At this time, due to the more stable and reliable performance of plywood, plywood has been widely used in construction, transportation, aviation and other fields. In the 1980s, with the increase of synthetic materials, the material of plywood gradually expanded, and the application range of plywood became wider. At the same time, the quality of plywood has also been greatly improved, so more and more families have begun to use plywood for interior decoration.

In recent years, as the country’s requirements for environmentally friendly building materials have become higher and higher, environmentally friendly plywood has been widely used. The glue used in environmentally friendly plywood materials is environmentally friendly glue, which does not contain harmful substances such as formaldehyde, and protects people’s health and the environment.

3. Innovation of plywood technology

With the continuous emergence of various new technologies, the plywood industry has also been further developed and innovated. In recent years, a new type of board called “cork board” has appeared. It is a new type of plywood made of cork raw materials and mineral oil. It has good sound insulation, heat preservation, waterproof and strong properties.

In addition, the original plywood is mainly used in construction, machinery, vehicles, etc., but with the rise of the Internet industry, the application range of plywood is also expanding. Now more and more plywood is used in the production of electronic products such as computers, mobile phones, flat-screen TVs, and laptops. The shells of these products are all made of plywood, replacing the original materials such as aluminum alloy, plastic, and glass.

4. Prospects for future plywood technology

In the future, people will continue to develop new plywood materials. In terms of material properties, plywood will be more environmentally friendly, lightweight, wear-resistant, and high in structural strength in the future. At the same time, with the development of technology, the production and processing methods of plywood will also change.

Development of plywood-free technology

Traditional plywood is made by bonding layers of wood or wood chips to each other. In the future, in the production process of plywood, with the increasing importance of environmental protection and sustainable development, a new plywood-free technology will emerge. This technology can combine natural wood so that it maintains its structure and strength, and increase the compactness of the material through micro-mechanics or physics, so as to achieve a tight bond between wood.

Intelligent processing technology

In the future, intelligent processing technology will be more widely used in the production process of plywood. Intelligent processing technology can realize automatic production, reduce labor costs, and control processing accuracy and production speed. At the same time, it can also reduce the cost pressure on seed resources, speed up the production cycle, and significantly improve production efficiency.

Application of lightweight materials

In the future, plywood production will pay more attention to the development of lightweight materials. Lightweight plywood can be lighter in weight, which reduces transportation costs and makes construction easier. In the future, scientists will continue to research and innovate, develop more and lighter materials, and further promote the development of the plywood industry.

In conclusion, as a widely used material, plywood has been continuously developed and innovated in its production and processing technology, thus enhancing its role in construction, transportation, electronics and other fields. With the continuous improvement of environmental protection awareness, the plywood industry will also continue to improve its technical level to better meet the needs of the market and society.