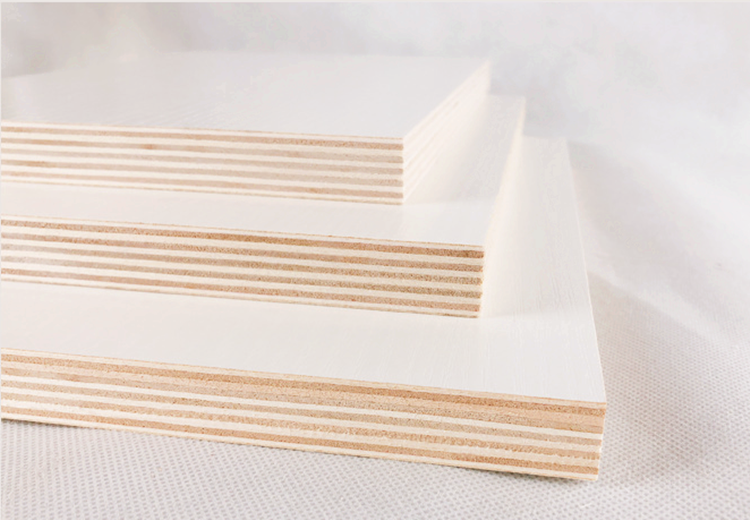

Plywood is a board made of layers of wood or other materials bonded together with an adhesive. It usually consists of three to seven layers of thin plates that are oriented perpendicular to each other to increase the stability and strength of the board.

The manufacturing process of plywood includes the following steps. First, the raw material, such as wood or other cellulosic material, is sliced and treated as required, such as peeling, flattening and drying. These sheets are then laid out in a specific order and orientation and coated with adhesive. Commonly used adhesives include urea-formaldehyde resins, phenolic resins, and epoxy resins. Subsequently, the sheets are pressed together under high temperature and pressure until the adhesive is fully cured.

Plywood offers many advantages such as:

1. Strength and Stability:

Due to the way it is constructed, plywood is more stable and stronger than solid wood boards.

2.Customizability:

Plywood can be customized as needed and used in a variety of different applications.

3. Inexpensive:

Compared to solid wood panels, plywood is less expensive to produce, making it an affordable choice in many applications.

4. Eco-friendly:

Using plywood can reduce the need for natural wood, and it can be recycled and reused.

Although plywood has many advantages, some precautions should be observed when using it to ensure its service life.

Storage and transportation

When storing and transporting plywood, care should be taken not to be exposed to moisture or sunlight to avoid warping and deformation. During transportation, appropriate protective measures need to be taken to avoid collision or friction between plates. When using plywood, relevant regulations and standards should be followed, such as stipulating that it should not be overloaded, not bent, or placed in a specific environment, etc.

1. Install

When installing plywood, it is necessary to choose a suitable plywood, which is suitable for the purpose and installation environment. Before installation, the plywood needs to be inspected and trimmed to ensure that its surface is smooth and even, free of cracks or defects. When installing, consider the direction and transverse direction of the board to avoid distortion or cracking of the board.

2. Maintenance

During use, plywood needs to be cleaned and maintained in time, especially in humid or high humidity environments. When encountering slightly damaged plywood, it should be repaired in time. When replacing plywood, the same material and specification should be selected to ensure the same size as the old board.

3. Environmental protection

During the production and use of plywood, the impact on the environment should be taken seriously. Using environmentally friendly plywood and adhesives, adopting low-energy-consuming gluing process, combined with measures such as waste disposal in the production process, in order to reduce the negative impact on the environment.

In short, reasonable use and maintenance of plywood is an important measure to ensure its long service life. Adopting environmentally friendly plywood and proper use, avoiding inappropriate usage and storage methods as far as possible, help to ensure the safety, reliability and environmental protection of plywood.

Plywood is widely used in construction, furniture, vehicles, packaging and ships. In the construction industry, it is commonly used in structural components such as floors, walls and roofs. In the furniture industry, it is used to make furniture such as tables, chairs, chests and beds. In vehicle manufacturing, it is used in components such as interiors and skins of automobiles and aircraft. In the packaging industry, it is used to make various types of boxes and containers. In shipbuilding, it is used for components such as hulls, decks, and internal structures.

In conclusion, plywood is a very common and useful board product with advantages including strength, stability, customizability, cheapness and environmental protection.

3 thoughts on “Plywood Introduction”

Very useful information in this article! Thanks for sharing!

No thanks

So glad that our article helps!